Disassembler (DIS)¶

General Description¶

As products reach the end of their lifecycle, they often become more homogeneous compared to their initial manufacturing state. This poses challenges in terms of automated disassembly, sorting, and separation processes. Manual inspection is typically required to assess their condition and determine the necessary treatment based on the extent of damage or wear. AI presents numerous opportunities to optimize the infrastructure involved in material circulation within the economy. A key focus is leveraging AI algorithms that utilize cameras and other sensors to recognize and identify objects. These algorithms aim to model the disassembly and recycling processes, predicting the outcome of each action by analyzing probabilistic relationships among various disassembly, sorting, separation, and recycling aspects. The goal is to develop a data-driven model that can identify the most suitable end-of-life solution for old machines, taking into account factors such as energy consumption, safety, maintainability, productivity, and technological advancements. This will involve advancements in AI technologies, specifically in the fields of visual recognition and machine learning.

Usage Viewpoint¶

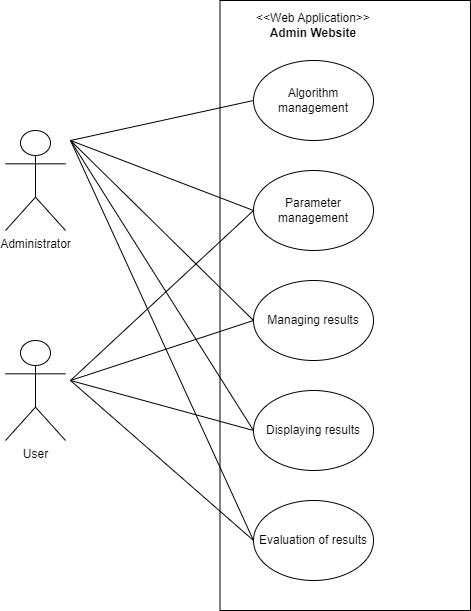

Use Model¶

Description¶

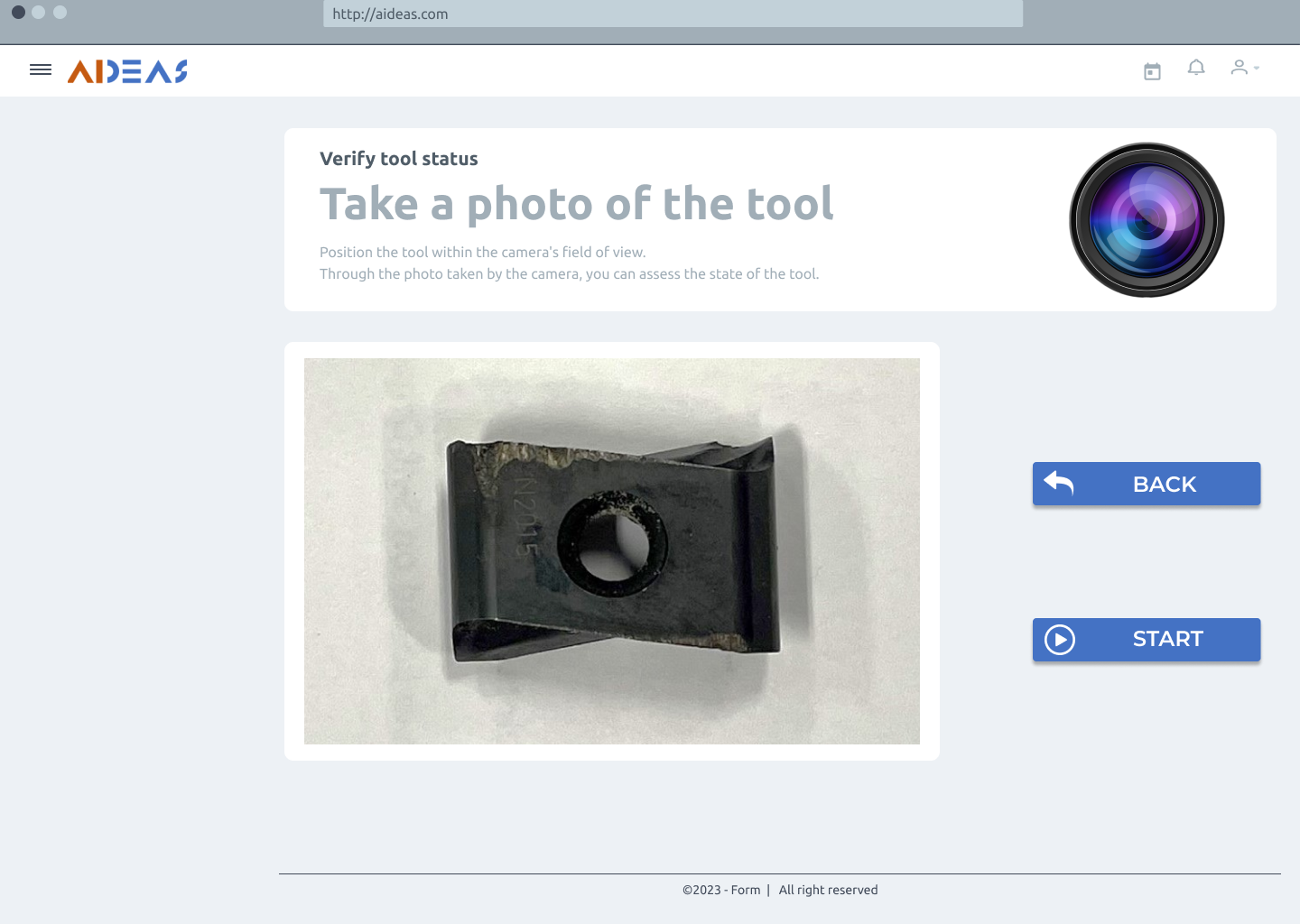

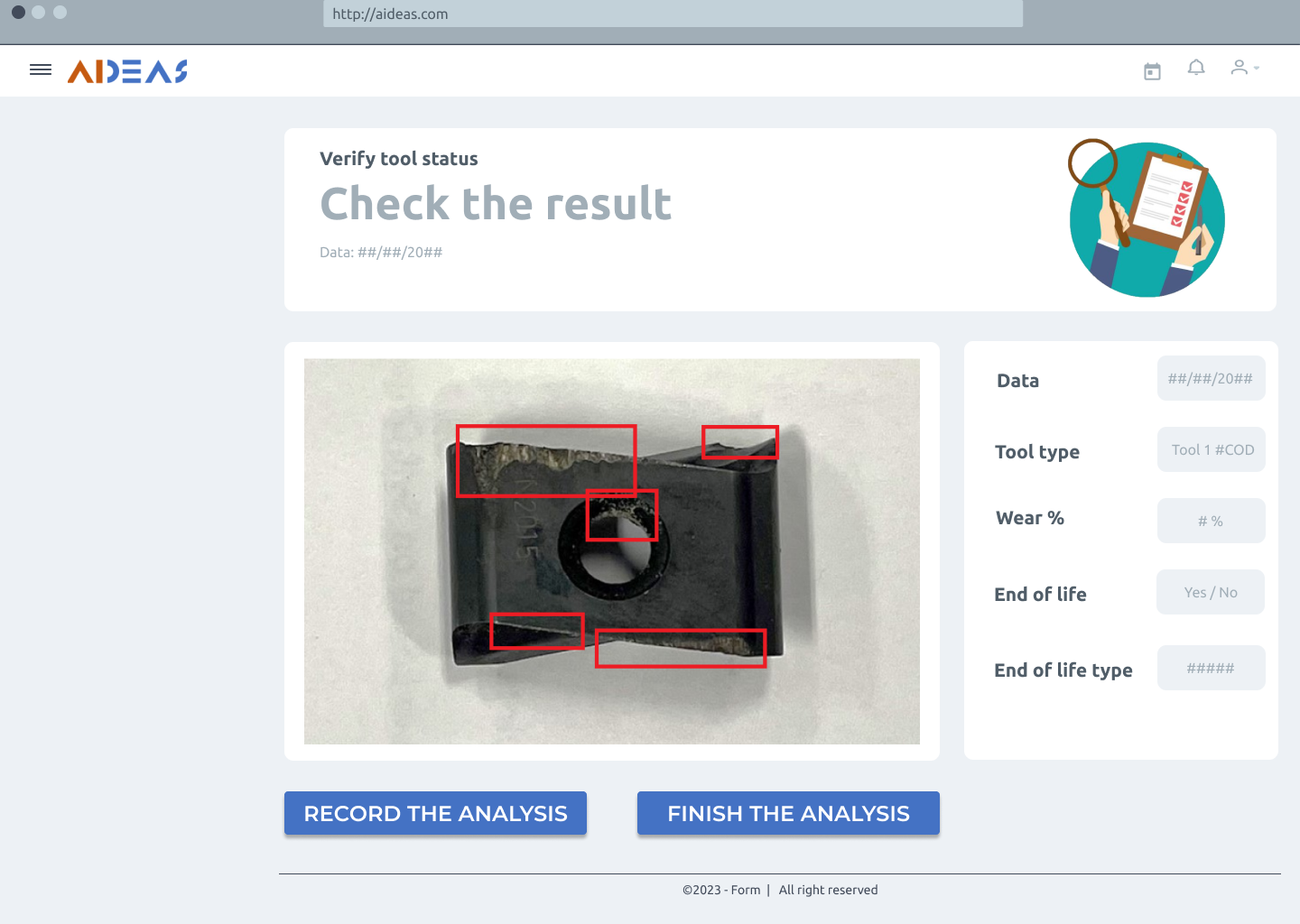

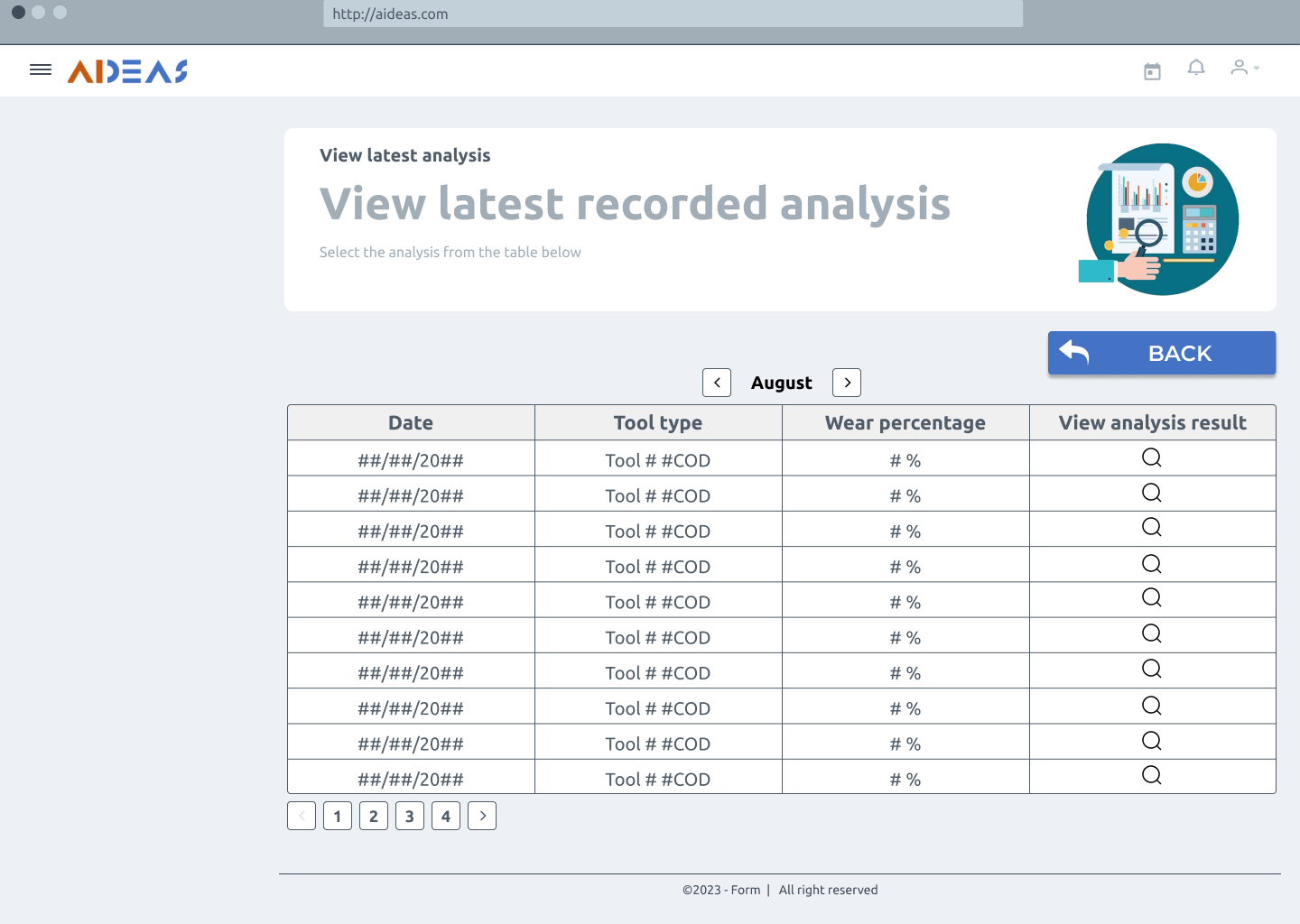

The AI-DSA solution serves as a disassembly support tool designed for industrial environments. This system incorporates industrial cameras capable of examining the present condition of various cutting tools, along with an artificial intelligence algorithm that can identify potential end-of-life scenarios for the analyzed tool. Prior to commencing the processing, the operator responsible for the turning process verifies the machine and cutting tool statuses. Upon logging into the AI-DSA system using their personal account, which is provided by the administrator, the operator can initiate the tool analysis. The artificial intelligence algorithm integrated into the system is pre-trained to recognize diverse object categories. In the event that a new category of cutting tools needs to be recognized, only the administrator can access the algorithm and perform the necessary training. The AI-DSA system maintains a record of all conducted analyses, storing them in a database accessible to both the user and the administrator. This enables the tracking of analysis history.

Identification¶

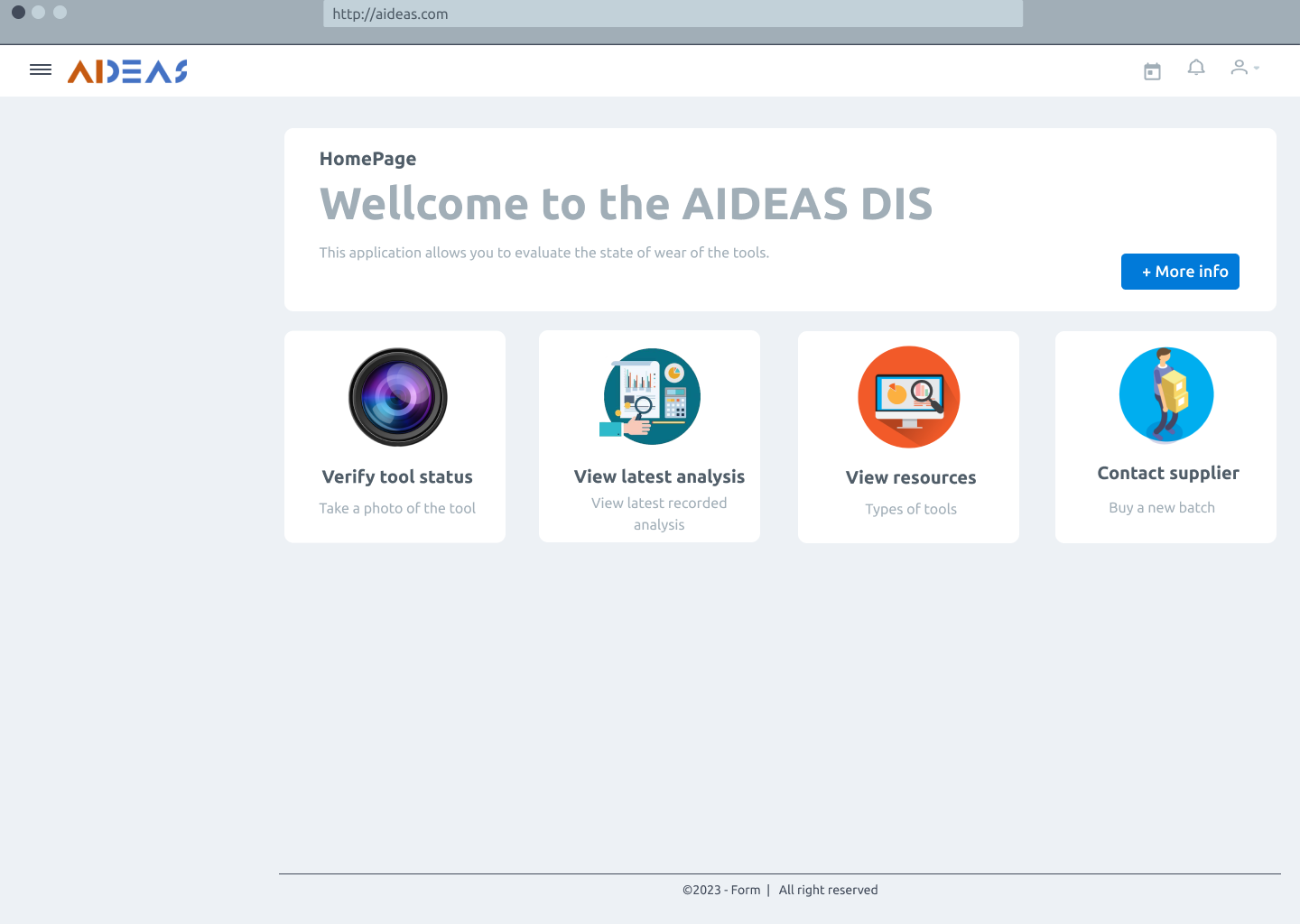

Home page¶

Verify tool status¶

Check the result¶

View latest recorded analysis¶

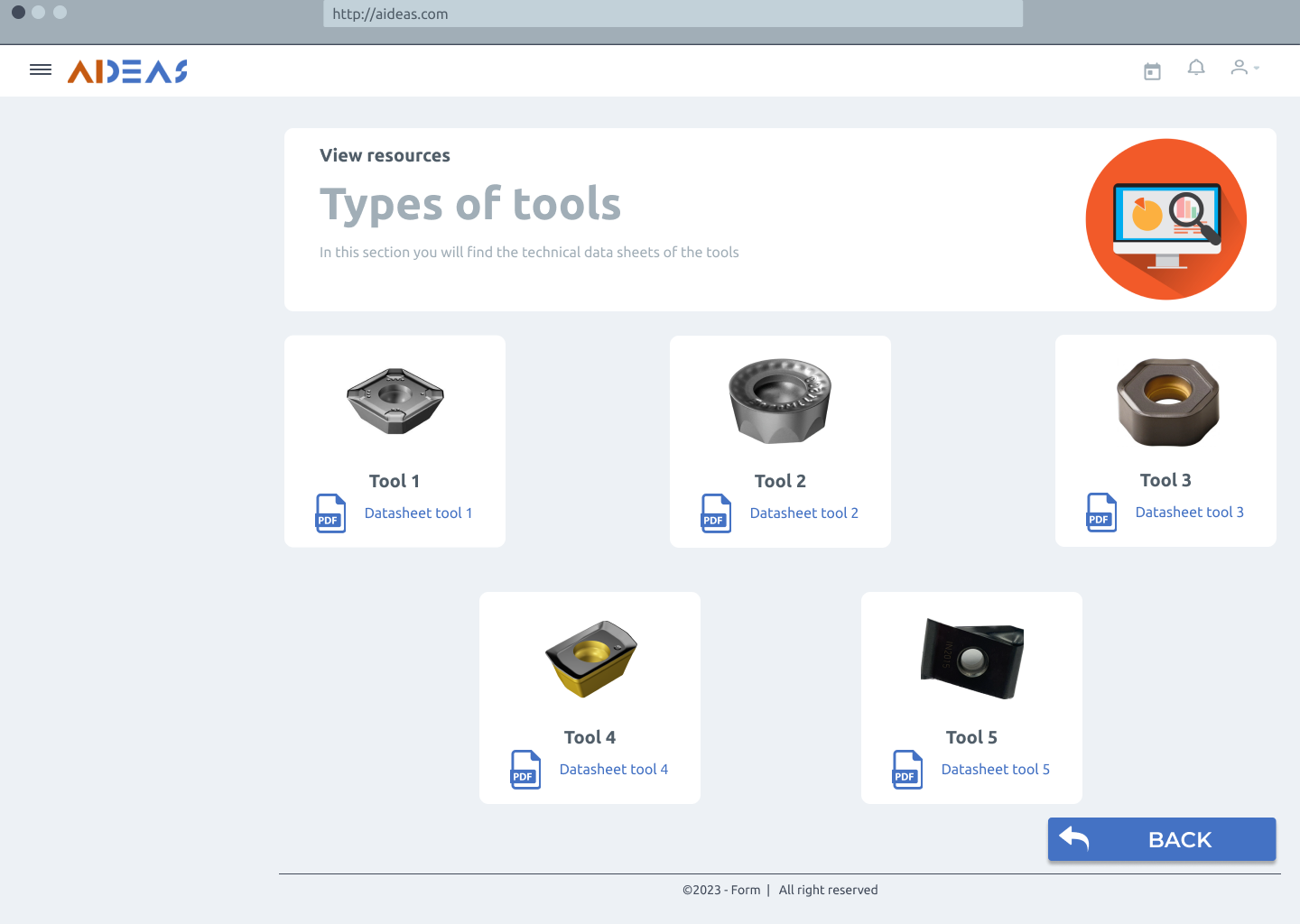

View resources¶

Contact supplier¶

Usage activity diagram¶

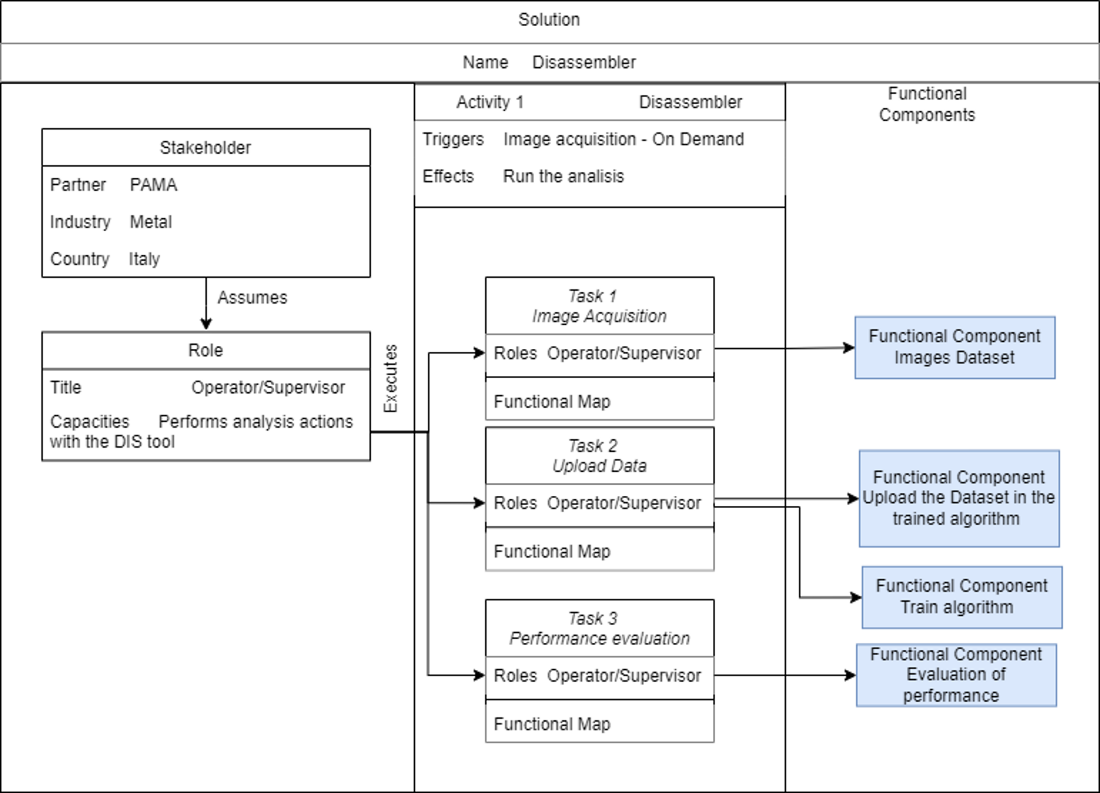

The following image shows the interaction between different tasks and roles. This diagram illustrates the dynamic flow of interactions, offering a representation of the activities performed by the solution and providing a clear understanding of the activities performed with the AIDIS solution.

Functional Viewpoint¶

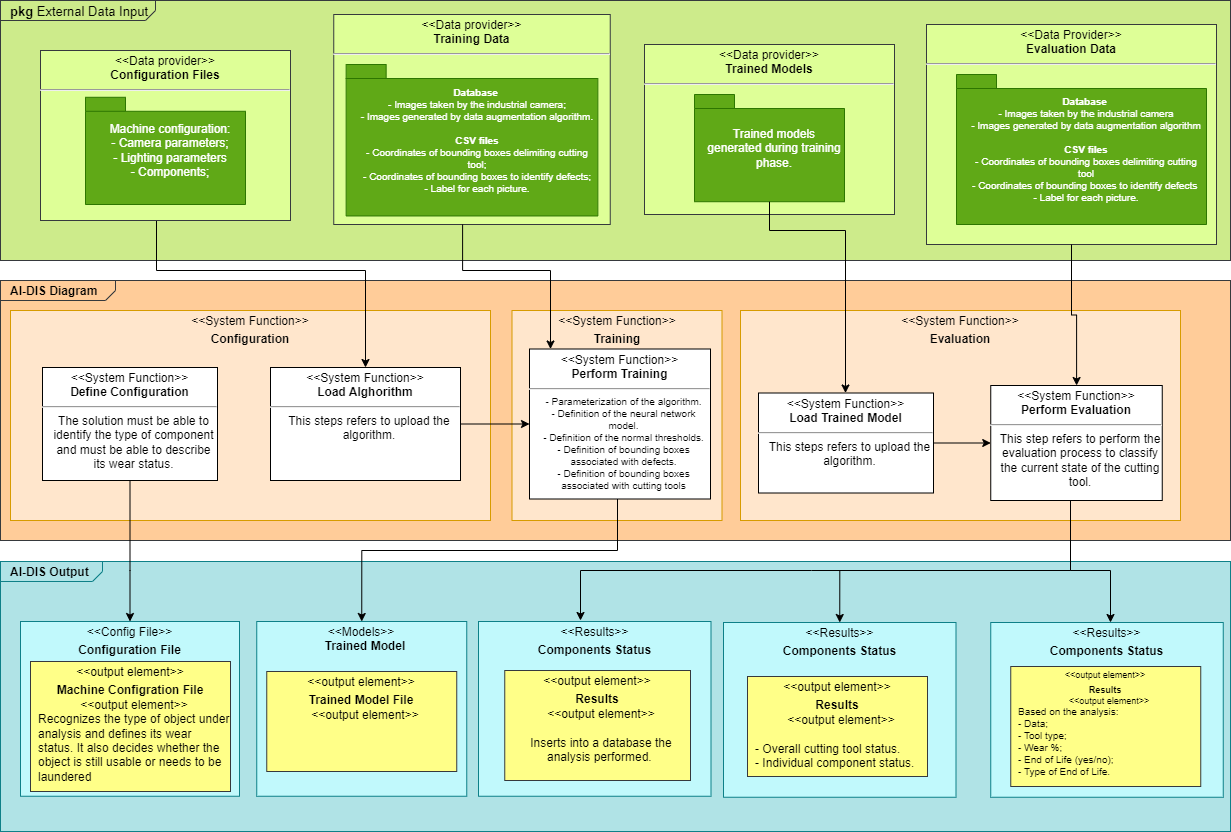

Functional diagram¶

Functional description¶

What: The main feature of this component is to check the condition of cutting tools with the aim of finding out whether they are still usable or need to be disposed of.

Who: Production managers. Maintenance operators

Where: Cutting tools

Why: Several industrial processes are needed to produce well-made machines; if even one of them is poor, it would result in a poor result. This component is used to identify the state of the cutting tools with the purpose of ensuring the quality required to complete the process of turning.

Input and output data for each component¶

Define Configuration¶

Inputs:

Cutting tools: Cutting tools that are to be recognized by the algorithm.

Type of defects to be identified: Breakdown of defects by type of category.

Outputs:

Algorithm configuration file: This file will contain information on both the images to be used to train the network and the bounding boxes to describe defects.

Load Algorithm¶

Inputs:

Training Data

Outputs:

Final structure of the neural network model to be used.

Perform Training¶

Inputs:

Training data: set of photos collected by the industrial camera and set of csv files containing the defect areas of the cutting tools.

Normal thresholds: thresholds must be chosen to go to identify the defects present within the input photos.

Algorithm training: the algorithm is trained with the input data.

Outputs:

Trained Model: once the training process has finished, a model could be downloaded from the frontend to be used as an input for the evaluation process. Model file extension is h5 or hdf5.

Load Trained Model¶

Inputs:

Model trained and generated during training phase.

Outputs:

Trained model statistics.

Perform Evaluation¶

Inputs:

Evaluation data: set of data, other than training data, collected from a database and uploaded to a csv file.

Outputs:

Data: data of analysis;

Tool type: type of cutting tool;

Wear %: Wear rate of the cutting tool;

End of Life (yes/no)

Type of End of Life: Based on the wear rate of the tool recommends the type of end of life.

Hardware requirements¶

Hardware Element |

Importance and Explanation |

Data of Element |

|---|---|---|

Industrial camera |

A high-resolution camera for image acquisition in industrial field |

Example: Triton2 20 MP Model (IMX183), Fujinon, 50 mm, 1.1”, 23MP |

Software requirements¶

Software Component |

Description/Role |

Required Version/Configuration |

Dependencies |

|---|---|---|---|

Linux OS or Windows OS |

Operating system needed to use the tool |

Ubuntu 22.04 / Windows 10 Pro |

N/A |

Docker |

Build, share and run containers |

latest |

N/A |

Lifecycle¶

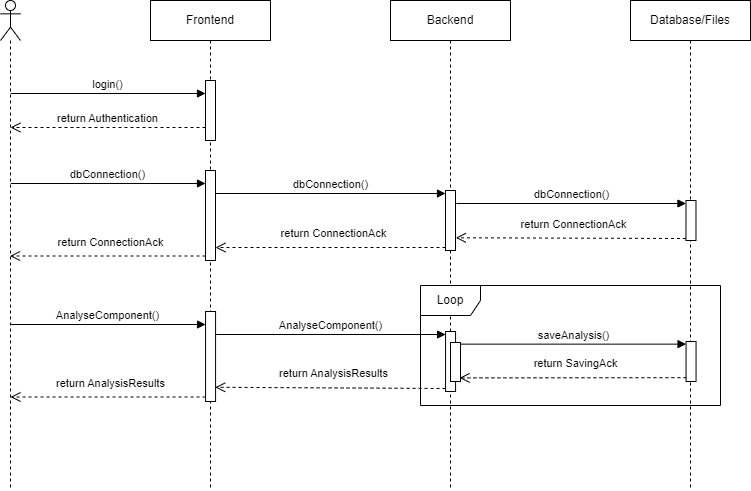

This sequence diagram illustrates the flow of interactions between the User, Frontend, Backend, and Data/Files objects during the main processes. Login into the AIDEAS platform, establish a connection to an internal/external database, acquiring image from equipment, and analyse it.

Objects¶

User: Represents the User interacting with the application.

Frontend: Represents the user interface and the presentation layer.

Backend: Represents the application logic and the server layer.

Database/Files: Represents the data or file storage layer.

Implementation Viewpoint¶

Description of implementation Component:¶

AI-DIS is a tool in support of quality management of products being disassembled.

Technical Description of its Components:¶

Dependencies:

Development Language: - Python.

Libraries: Keras, sklearn, Numpy, Matplotlib, Pandas, Tensorflow, Plotly, OpenCv.

Container: Docker.

Database need: MySQL.

Interfaces:

User Interface: WordPress.

Synchronous/Asynchronous Interface: RESTful APIs.

Network/Protocols: HTTP/HTTPS.

Data Repository: MySQL.

Requires:

Other AIDEAS Solutions: none

Solution architecture¶

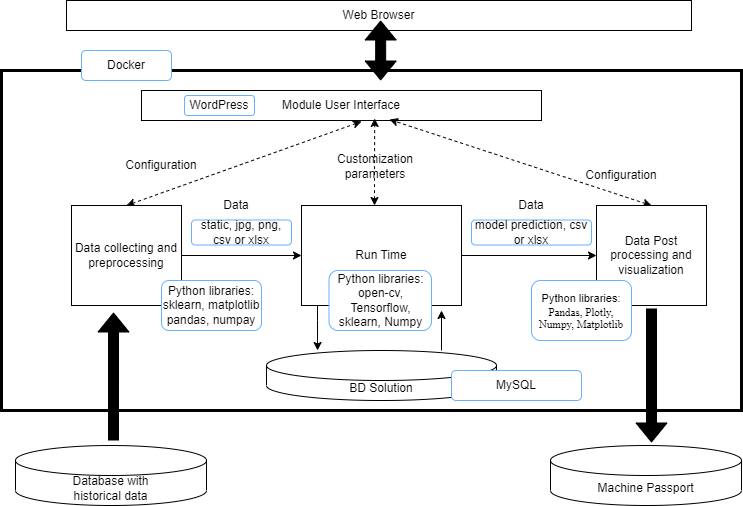

The AI-DIS solution will be developed using Python as the primary programming language, leveraging widely-used libraries in the fields of data science and machine learning. These libraries encompass NumPy for efficient processing of arrays and matrices, Pandas for comprehensive data analysis and manipulation, and SciPy, Keras, and TensorFlow for training and evaluating machine learning models. Additionally, OpenCv will be employed to handle image manipulation captured by the industrial camera, while both Matplotlib and Plotly will facilitate graphical representation.

For the frontend development of AI-DIS, the WordPress software will be utilized. The backend and frontend will communicate through a RESTful API, ensuring secure data transmission using HTTPS protocols. All data will be stored in a MySQL database.

To enhance software portability and streamline deployment, Docker will be employed. Docker offers a platform to package all necessary dependencies and components, simplifying the execution of the software.