Machine Passport¶

General Description¶

The development of the Machine Passport for storing and sharing manufacturing data throughout the product life phases is a crucial aspect of ensuring efficient data integration, sharing, and exchange in the industry. The MP aims to establish data exchange protocols, standards, and interfaces that facilitate seamless communication between various computer-aided systems and manufacturing stages.

To achieve this goal, the MP can leverage a combination of technologies and standards. One approach is to utilize standardized data exchange formats such as XML (eXtensible Markup Language) or JSON (JavaScript Object Notation) to represent and structure the manufacturing data. These formats provide a common language for different systems to understand and process the data.

In terms of data storage, a suitable database management system can be employed to efficiently store and retrieve the manufacturing data. Depending on the specific requirements of the MP, a relational database management system (such as MySQL or PostgreSQL) or a NoSQL database (such as MongoDB or Cassandra) can be chosen.

To ensure secure and reliable data exchange, the MP can employ authentication and encryption mechanisms. Secure communication protocols such as HTTPS (Hypertext Transfer Protocol Secure) can be utilized to protect the integrity and confidentiality of the data during transmission.

Additionally, the MP can incorporate industry-specific standards and protocols such as OPC-UA (OPC Unified Architecture) or MTConnect to facilitate interoperability between different manufacturing systems and equipment. These standards define a common set of rules and protocols for data exchange, enabling seamless integration and sharing of manufacturing data.

Overall, the development of the Machine Passport involves designing data exchange protocols, selecting appropriate storage mechanisms, incorporating security measures, and adhering to industry standards. By establishing efficient data integration, sharing, and exchange capabilities, the MP contributes to streamlining manufacturing processes and improving collaboration across different stages of the product life cycle.

Usage Viewpoint¶

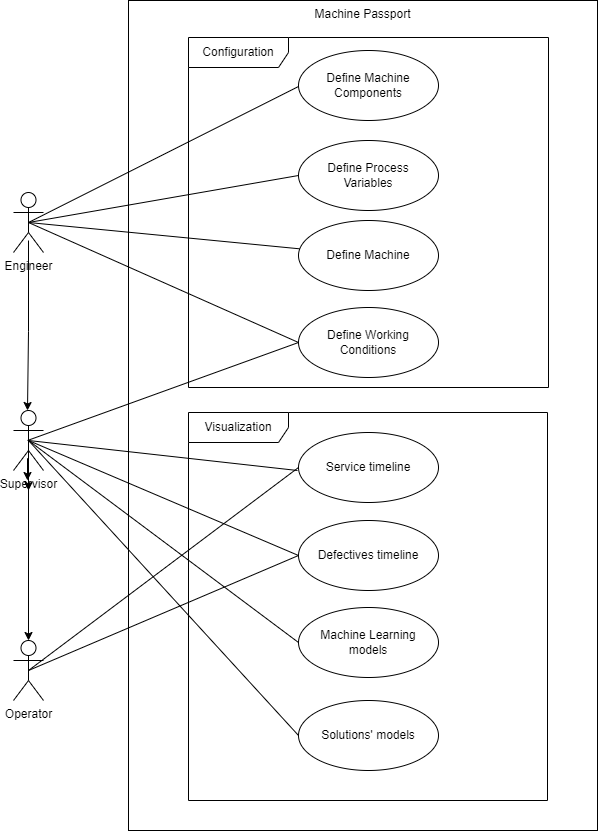

Use Model¶

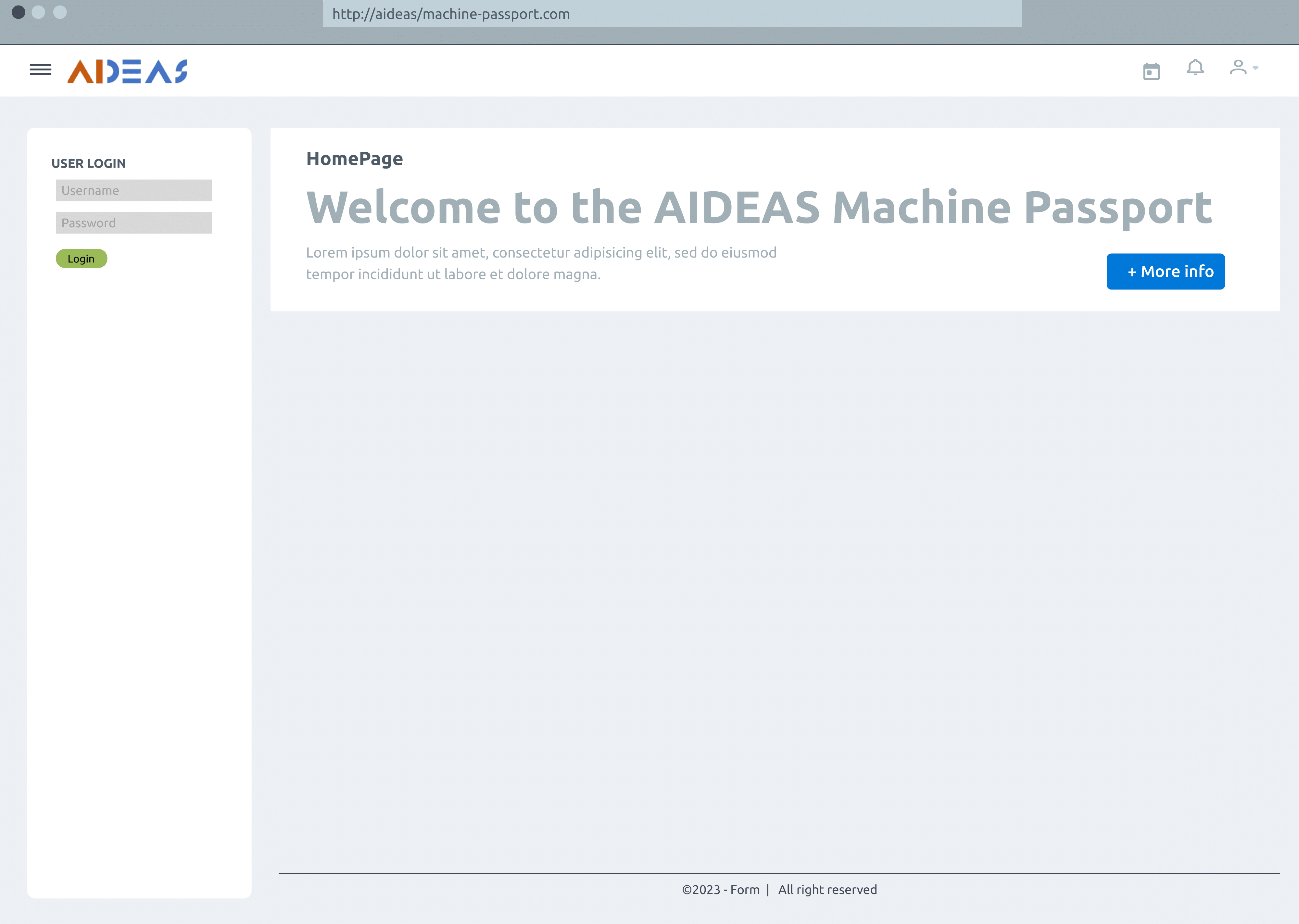

Home page¶

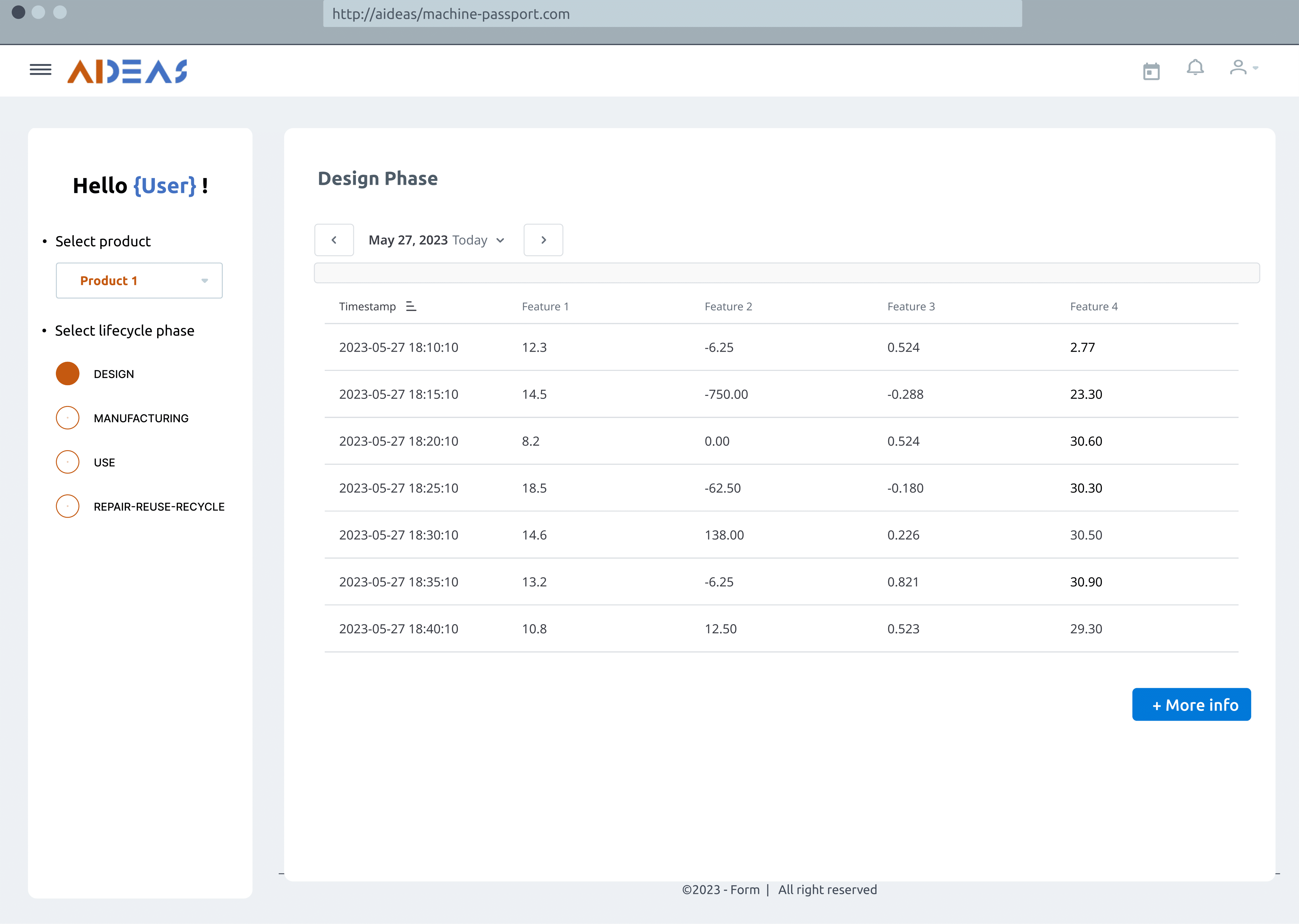

Select lifecycle phase¶

Usage activity diagram¶

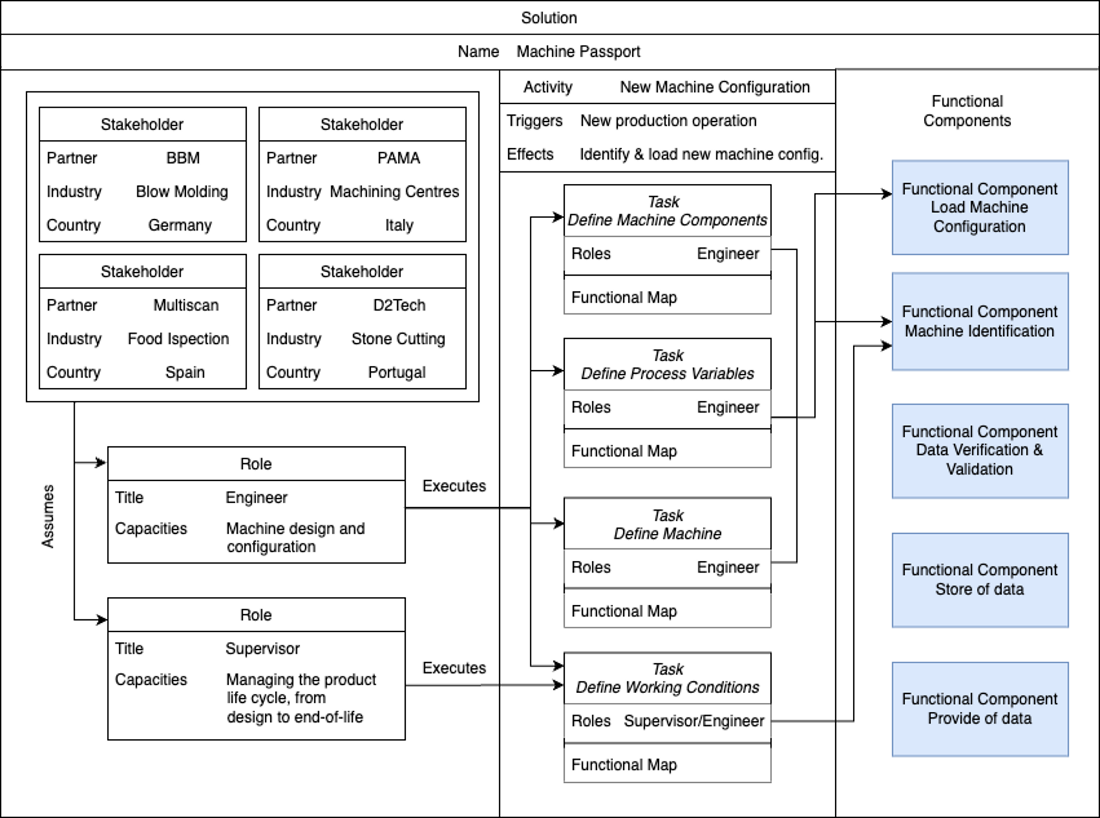

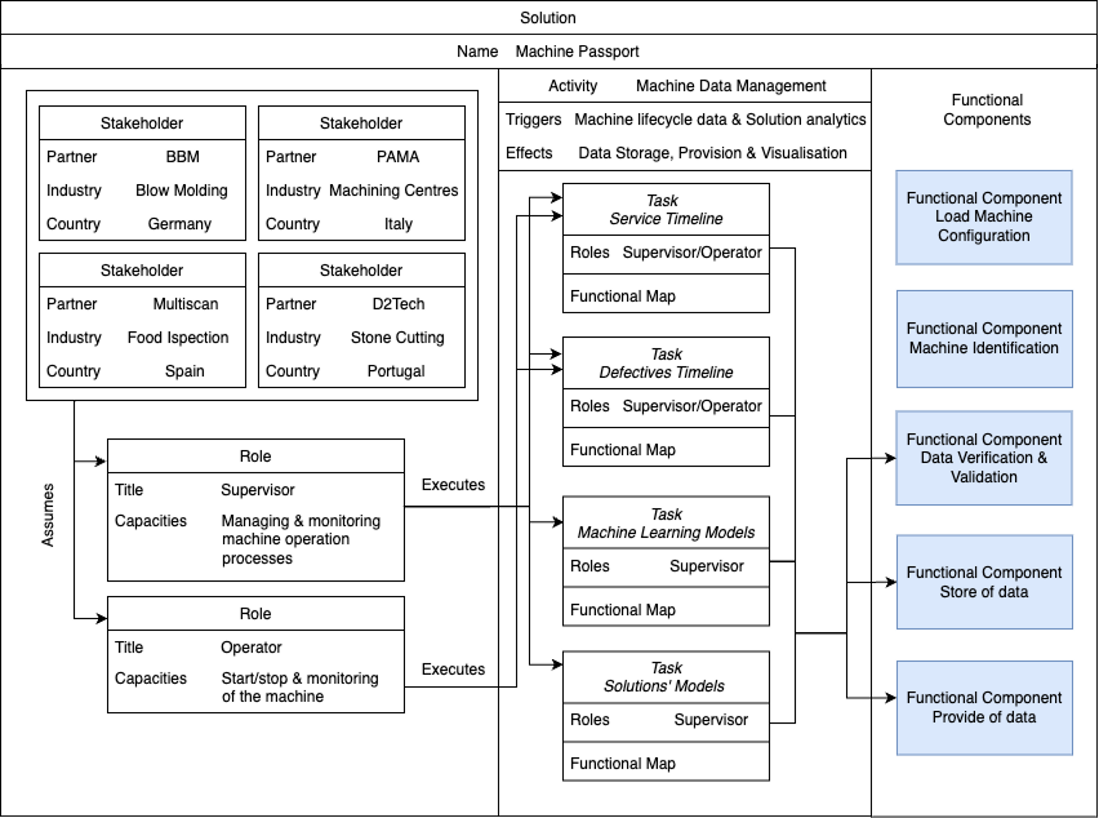

The following image demonstrate the interaction between the different tasks and roles. No distinction between pilots is made, as the solution’s functionality remains consistent across various use cases and stages of the product life cycle. These diagrams depict the dynamic flow of interactions, showcasing the activities performed by the AIMP solution. They provide a clear understanding of the operational processes and collaborative engagements among different tasks and roles.

Machine configuration¶

Machine data management¶

Functional Viewpoint¶

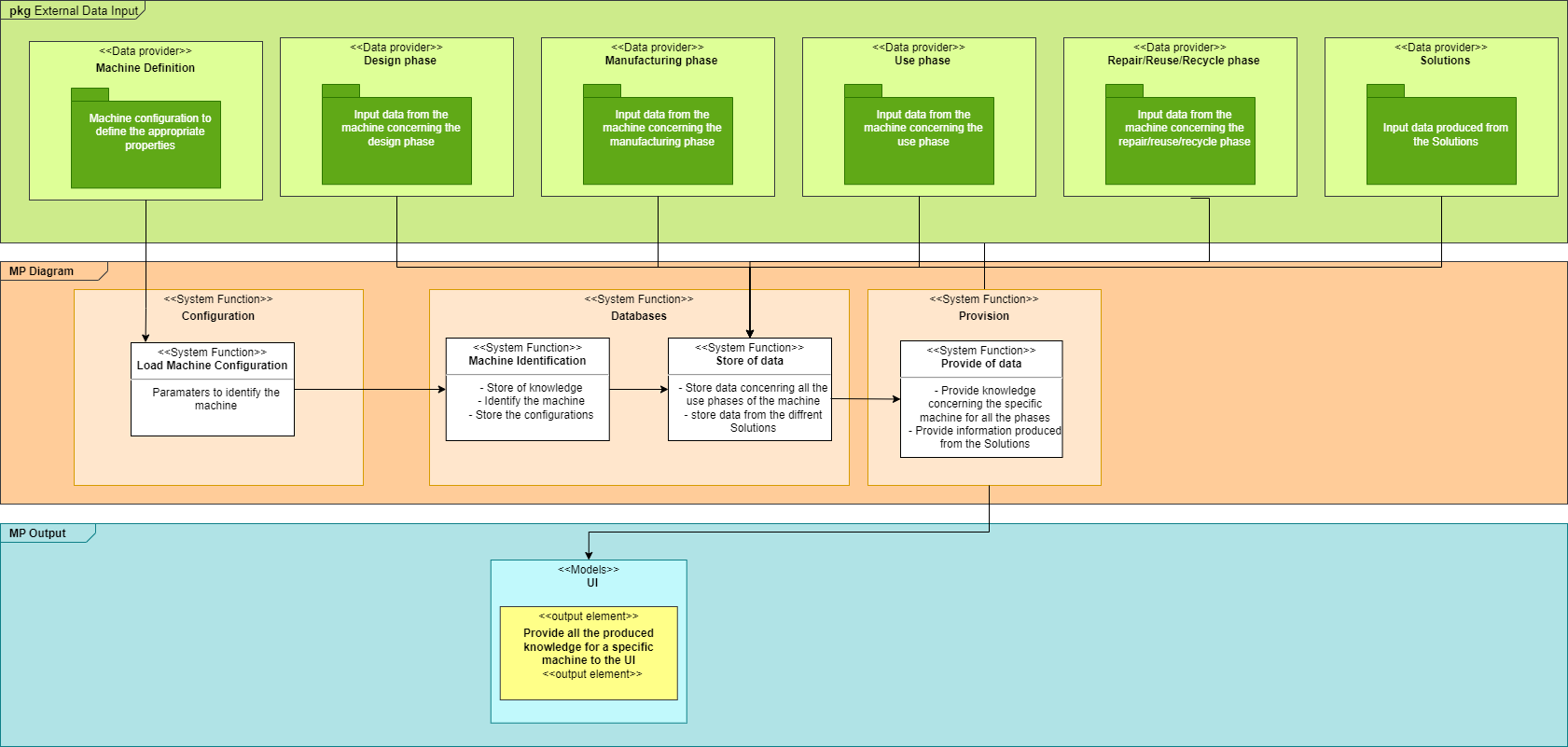

Machine Passport Functional Viewpoint Description |

|

|---|---|

Description |

Machine Passport is responsible for storing and sharing manufacturing data that are obtained throughout the product life phases, i.e., Design, Manufacturing, Use, and Repair-Reuse-Recycle Data phases of Industrial Equipment. |

Inputs |

As inputs, we will have static and dynamic data. Static data will come from data files (csv, excel). The dynamic data will come from sensors and from the solutions. |

Outputs |

MP will contain functionalities to provide requested knowledge when it is requested. |

Hardware requirements¶

Hardware Element |

Importance and Explanation |

Data of Element |

|---|---|---|

Storage |

For the storage of knowledge coming from the solutions and data from different sources |

CSV file, JSON messages, APIs |

Server |

To be used as a smart data management platform for manipulating industrial data |

APIs |

Connectivity |

Connectivity with SQL databases, NoSQL databases and APIs |

APIs |

Software requirements¶

Software Component |

Description/Role |

Required Version/Configuration |

Dependencies |

|---|---|---|---|

LINUX |

Operating system to use the specific tool |

22.04 |

N/A |

NodeJS |

To run the component in the server |

20.10 |

N/A |

Docker |

To deploy the tool in the server |

20.10+ |

N/A |

Lifecycle¶

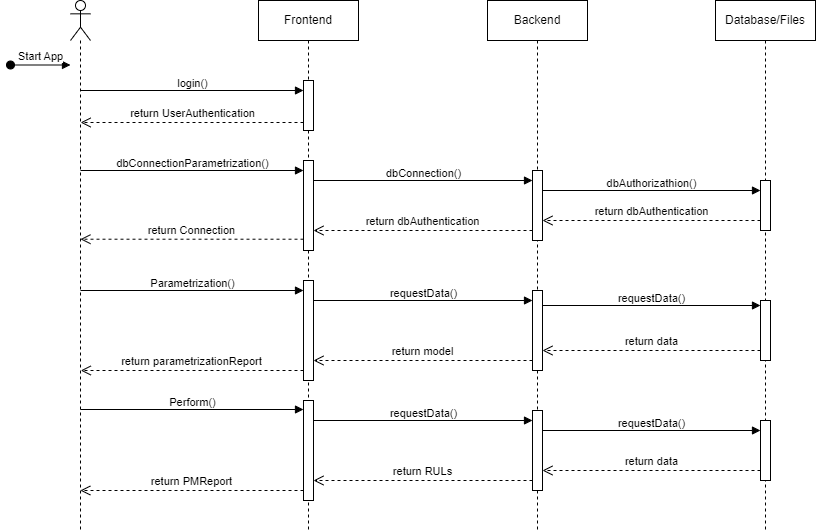

The AIDEAS Machine Passport component, as depicted in the sequence diagram, acts as a centralized platform for orchestrating the flow of data across the lifecycle of industrial equipment. It begins with user authentication through the frontend, ensuring secure access to the system. Subsequently, the dbConnectionParameterization() function is called to establish a secure connection to the backend, where dbAuthorization() verifies access rights, and upon successful authentication, a connection is established.

In the backend, the Machine Passport interfaces with the database/files system to request and retrieve data. The Parameterization() process is a critical step where specific parameters for data acquisition and processing are set. Upon completion, a report is generated and sent back to the frontend, indicating the successful configuration of parameters.

The Perform() function appears to trigger a more complex data processing or operational action, where data is once again requested from the backend. This request initiates a sequence of data retrieval from the database/files, which is then processed according to the specified business rules or logic (denoted by return RULs), and the resultant model or decision-making insight is returned to the frontend.

The Machine Passport’s role in this workflow is to ensure that data from various stages of the product life phases are not only collected and stored but also made readily available for advanced analysis. The data flow facilitated by the Machine Passport allows for smart, trustful data integration, reflecting the exchange protocols, standards, and interfaces developed for seamless interaction between computer-aided systems and manufacturing stages. By managing large-scale data acquisition and sharing, the Machine Passport enables real-time, informed decision-making backed by explainable AI, ensuring that the insights provided to the frontend for user consumption are both rational and interpretable. This comprehensive approach empowers stakeholders to make decisions that enhance the design, manufacturing, and end-of-life management of industrial equipment.

Objects¶

User: Acts as the authenticated gateway to the Machine Passport, initiating secure data transactions and interactions.

Frontend: Delivers a user-centric interface for precise data parameterization and seamless interaction with the Machine Passport.

Backend: Serves as the intelligence hub, processing data exchanges and integrating multifaceted manufacturing data within the Machine Passport framework.

Implementation Viewpoint¶

Description of implementation Component:¶

Responsible for data acquisition and sharing through all the phases of the products life.

Technical Description of its Components:¶

Dependencies:

Development Language: - JAVA.

Libraries: Spring Boot, postgresql, Lombok, JJWT.

Container: Docker.

Database need: MongoDB, Postgres.

Interfaces:

User Interface: No.

Synchronous/Asynchronous Interface: RESTful APIs.

Network/Protocols: HTTP/HTTPS.

Data Repository: MongoDB, Postgresql.

Requirements:

JAVA 17, JAVA IDE (Eclipse, InteliJ), Postgresql 15, MongoDB.

Installation process:

Import the component as a Maven project in the JAVA IDE, run Postgresql and MongoDB locally and run the main.java file in the IDE.

Solution architecture¶

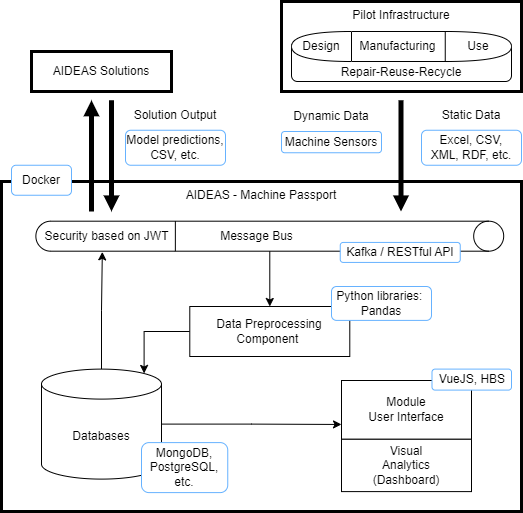

The MP solution is developed in Java using Spring Boot, PostgreSQL, Lombok, and JJWT, providing a robust and scalable platform for managing manufacturing data. Docker is used for containerization, enabling easy deployment and portability of the solution. The data repositories consist of MongoDB and Postgres, allowing for efficient storage and retrieval of manufacturing data.

The solution communicates through RESTful APIs, which follow the principles of Representational State Transfer (REST), enabling interoperability and seamless integration with other systems. The APIs use the HTTP/HTTPS protocols for secure communication and data exchange. This communications will go throught the Data Harmonizer, a component that works as middleware between the AI Machine Passport Backend and the AI Solutions to ensure that communications follow the predefined data schema for each solution and adhere to the standard.

To set up the solution, you would typically follow these steps:

Import the MP component as a Maven project in a Java IDE, such as IntelliJ or Eclipse.

Ensure that you have the necessary dependencies configured in the project’s Maven configuration file (pom.xml).

Set up local instances of Postgres and MongoDB databases. This may involve installing the database software and creating the required database schemas.

Configure the connection details for the databases in the application configuration files (e.g., application.properties or application.yml) of the MP solution.

Build and compile the project to generate the necessary executable files.

Execute the main.java file or start the application using the Java IDE’s built-in tools for running Java applications.

Once the application is running, you can interact with the MP solution through its exposed RESTful APIs using tools such as cURL or Postman.

It’s important to note that the MP solution does not have a user interface. Instead, it focuses on providing a backend infrastructure for storing and sharing manufacturing data through APIs. The APIs can be consumed by other applications or systems that require access to the MP functionality.

By following the setup process and utilizing the provided RESTful APIs, users can integrate the MP solution into their manufacturing systems and leverage its capabilities for managing and exchanging manufacturing data efficiently.