Machine Calibrator (MC)¶

General Description¶

The purpose of this tool is to assist the end user of the machine during the initial calibration process at the customer’s factory, tailored to meet the specific requirements of each customer and factory using AI techniques. Calibration is a crucial step for every machine upon its arrival at the customer’s premises, posing challenges for both the machine provider and the end user. To address this, the proposed solution leverages AI to facilitate the initial calibration process.

The primary goal is to employ a supervised learning approach that learns from experienced users and identifies the most suitable calibration parameters based on the specific processing needs. By doing so, this tool will offer calibration capabilities to all AIDEAS pilots, ensuring accurate and efficient machine calibration.

Usage Viewpoint¶

Use Model¶

Description¶

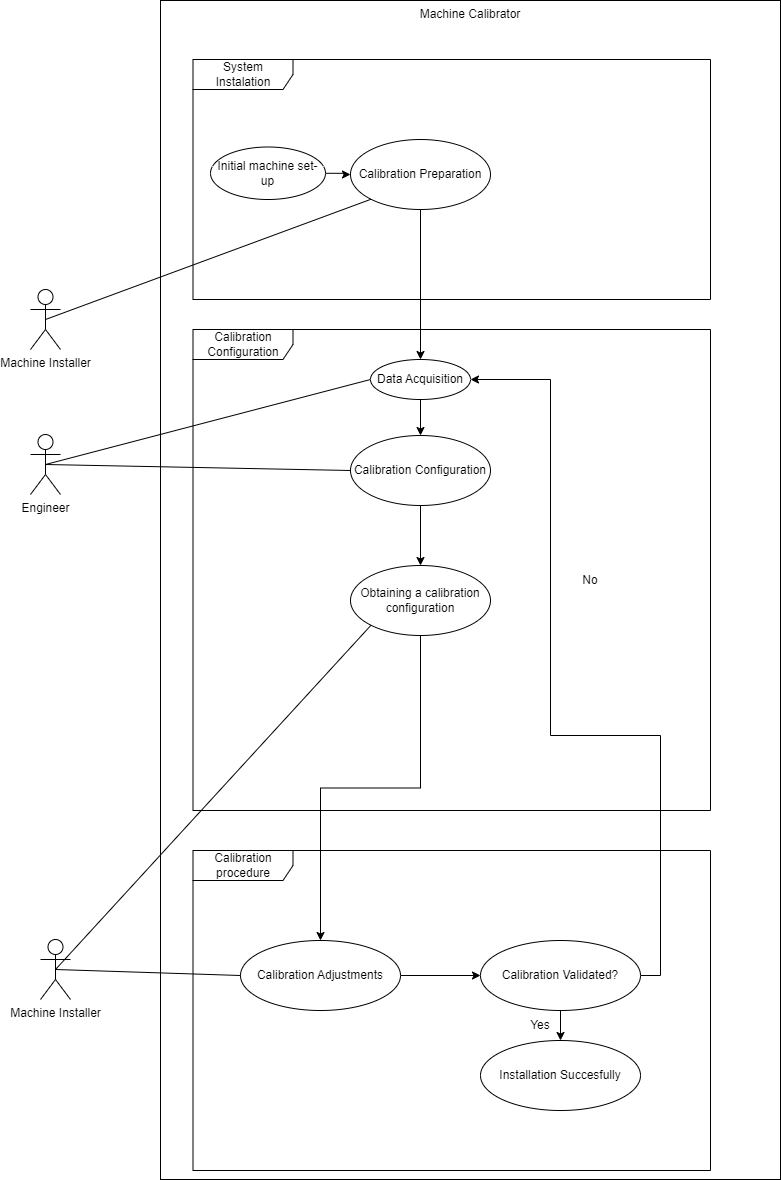

The primary actors involved in the AI-MC solution are the Machine Installation Specialist and the Engineer. The process begins with the Machine Installation Specialist inputting the machine’s initial configuration parameters and calibration settings. Subsequently, a data acquisition module collects data from the machine’s initial configuration and calibration preparation.

Next, the Machine Installation Specialist and the Engineer collaborate to build a model trained with data obtained from the calibration process. This results in a validated Calibration Configuration that incorporates parameterization profiles tailored to each specific situation. The Calibration Configuration assists the Machine Installation Specialist in performing the calibration task, following the guidelines provided by the Engineer.

The solution also includes a decision structure that monitors the effectiveness of the calibration. This information serves as a feedback variable within the system, aiding in the production of the calibration profile. The overall objective is to enhance the calibration process through the use of AI techniques, improving accuracy and efficiency.

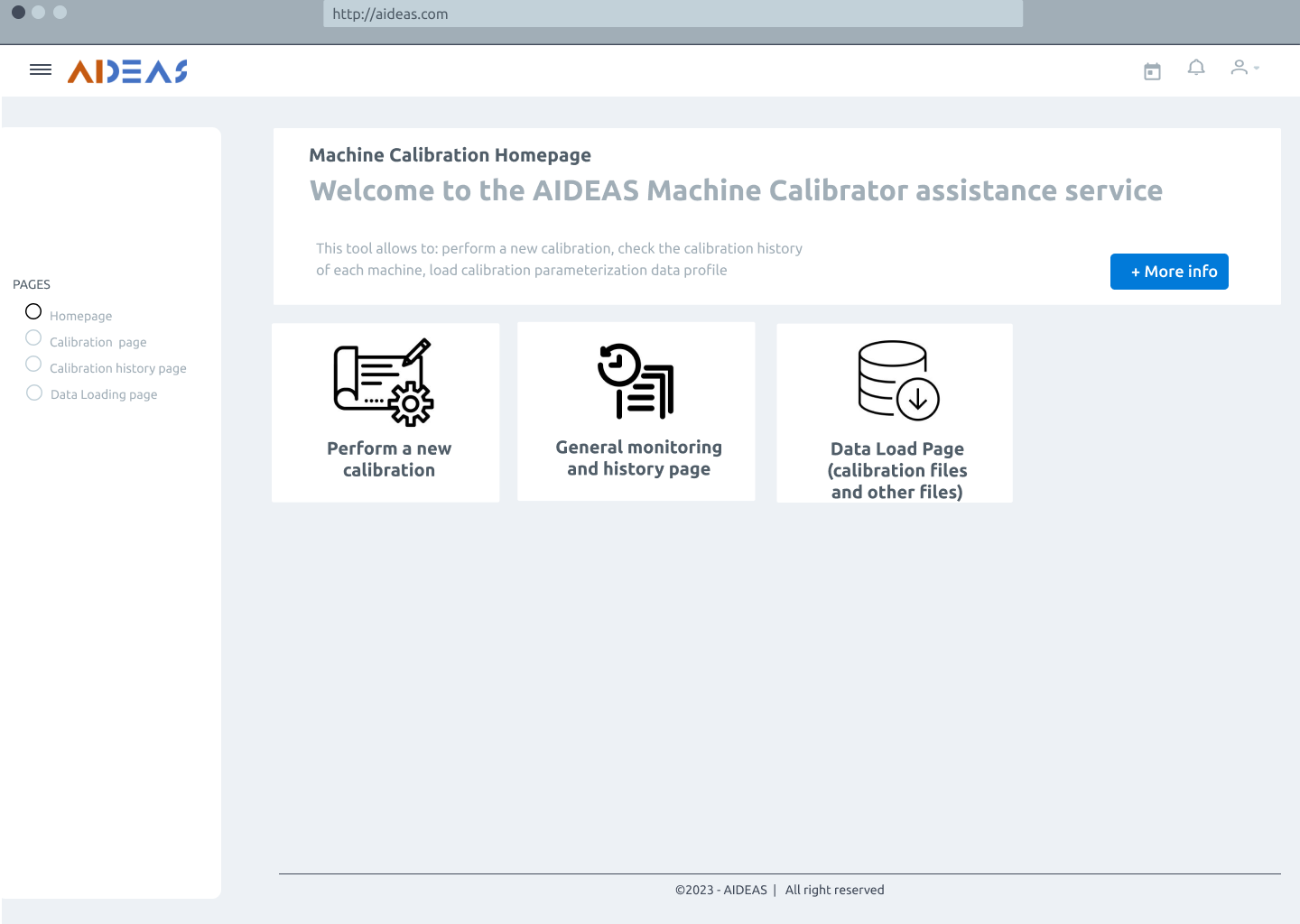

Home page¶

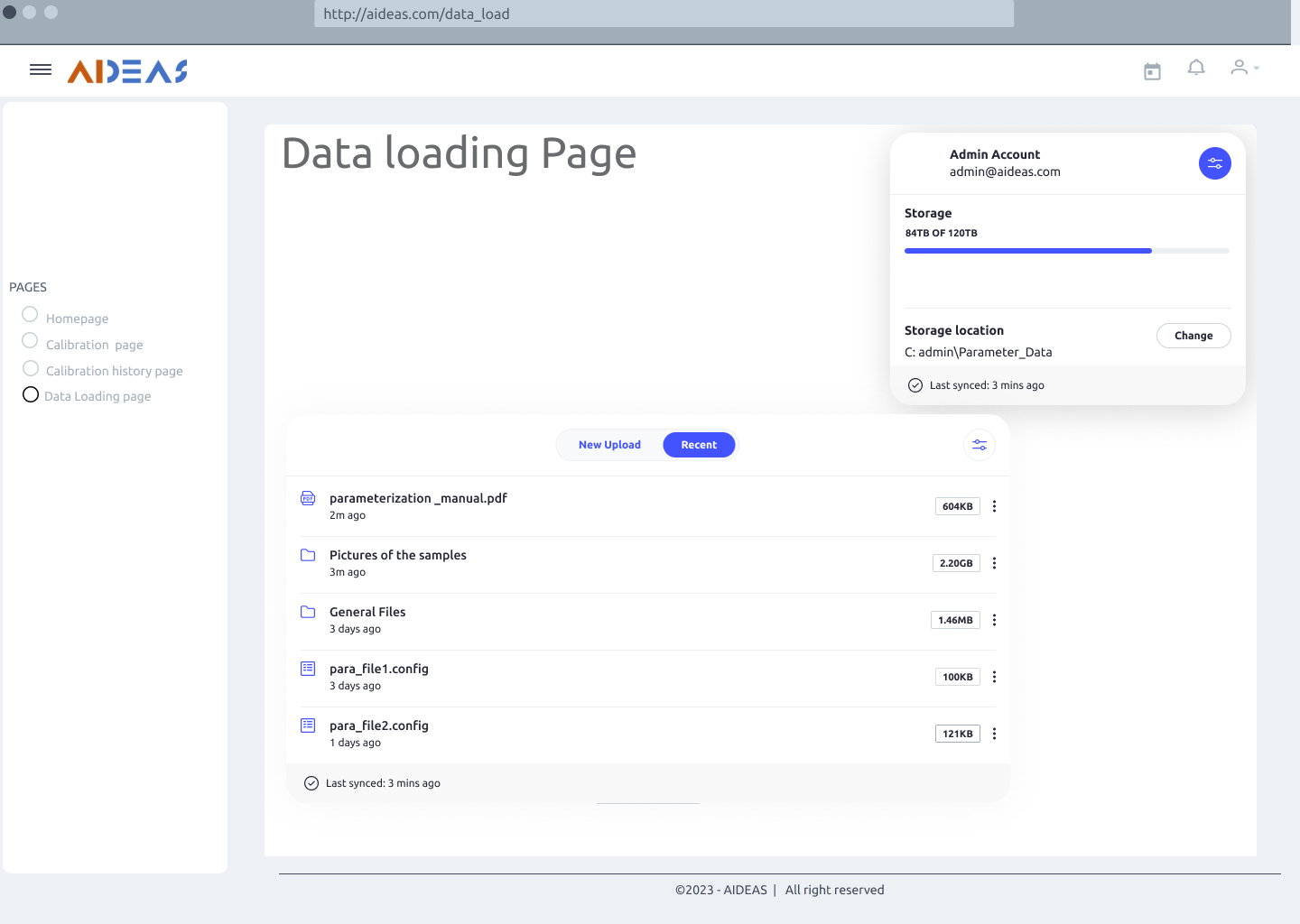

Data Loading page¶

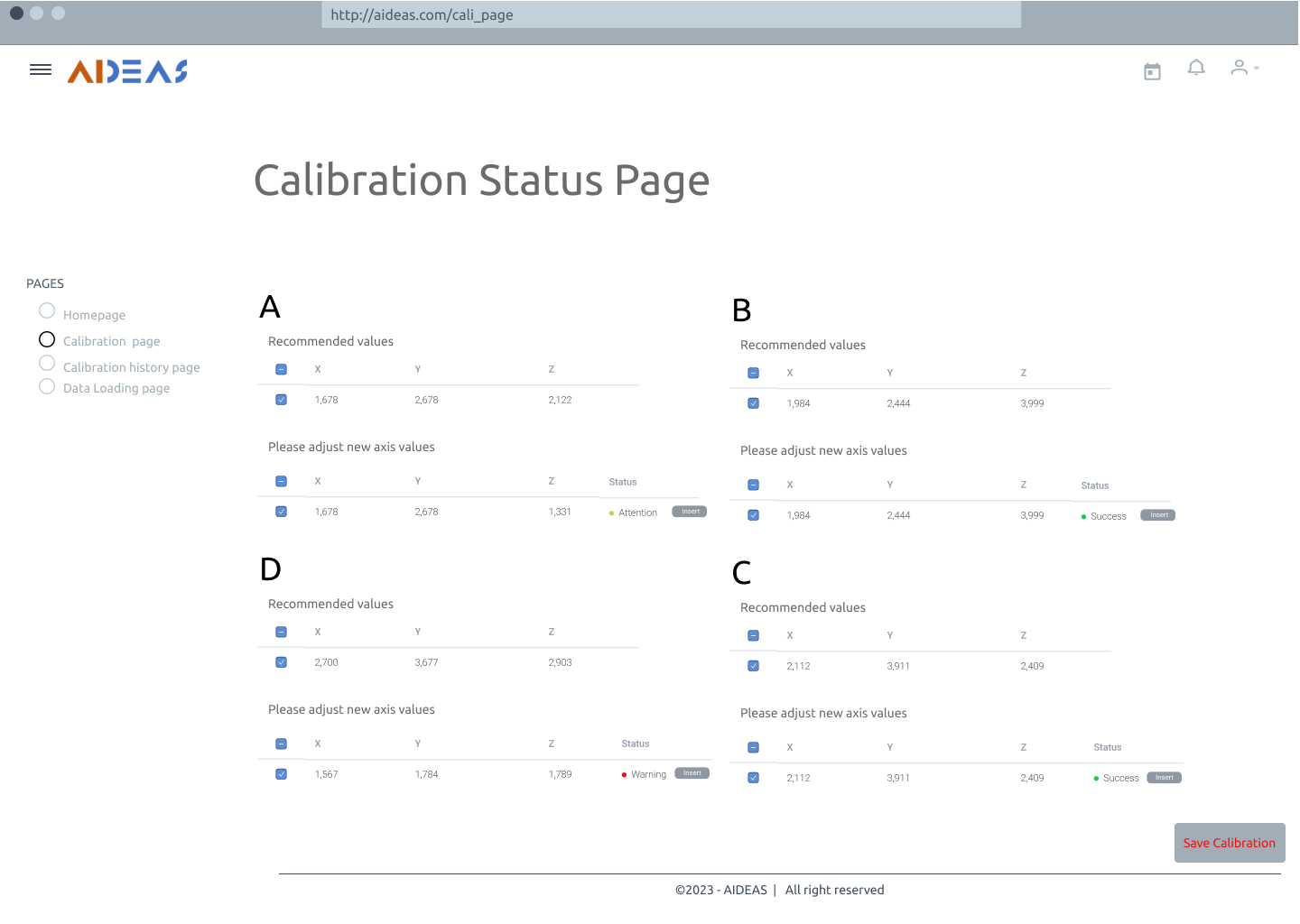

Calibration Status page¶

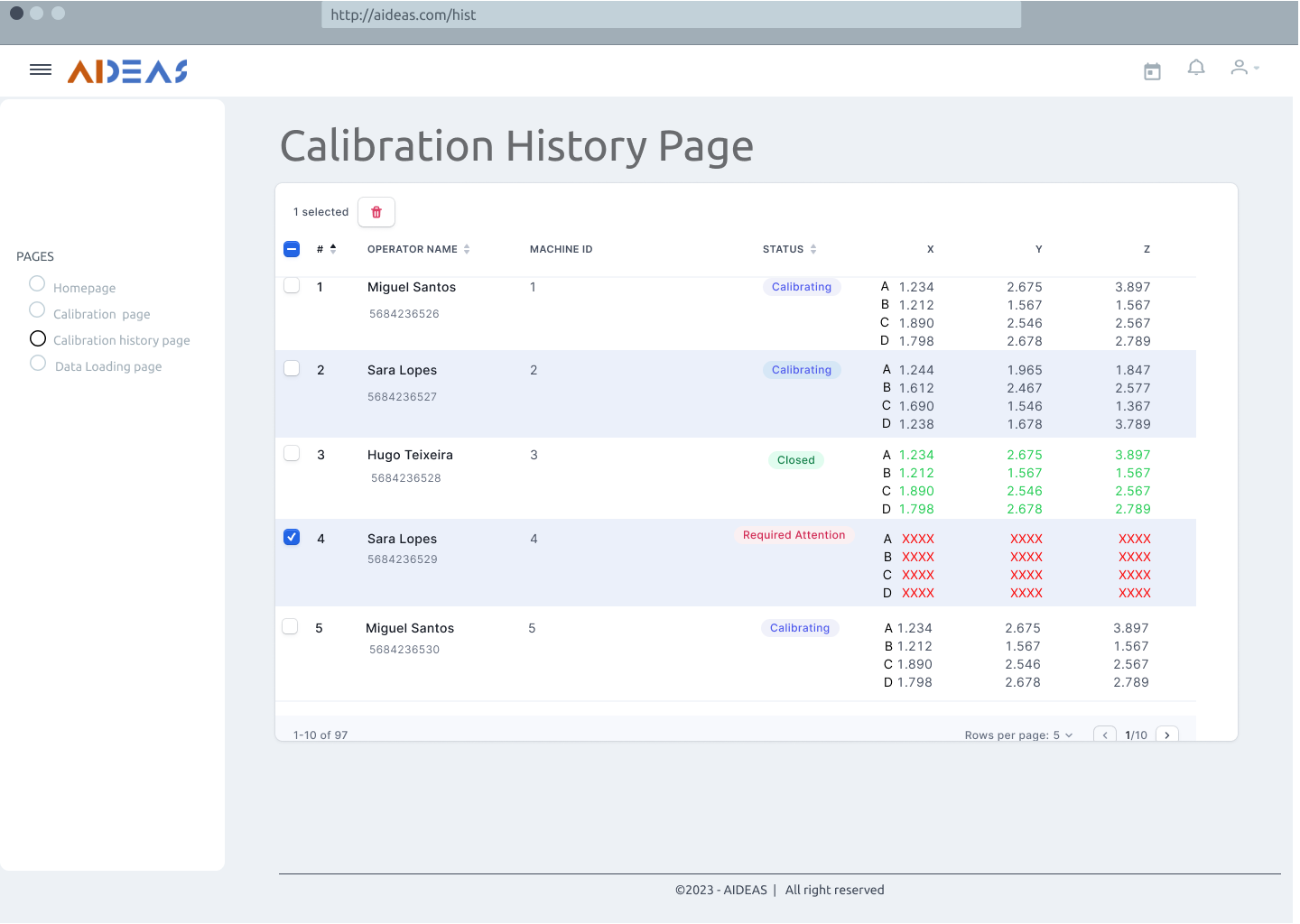

Calibration History page¶

Usage activity diagram¶

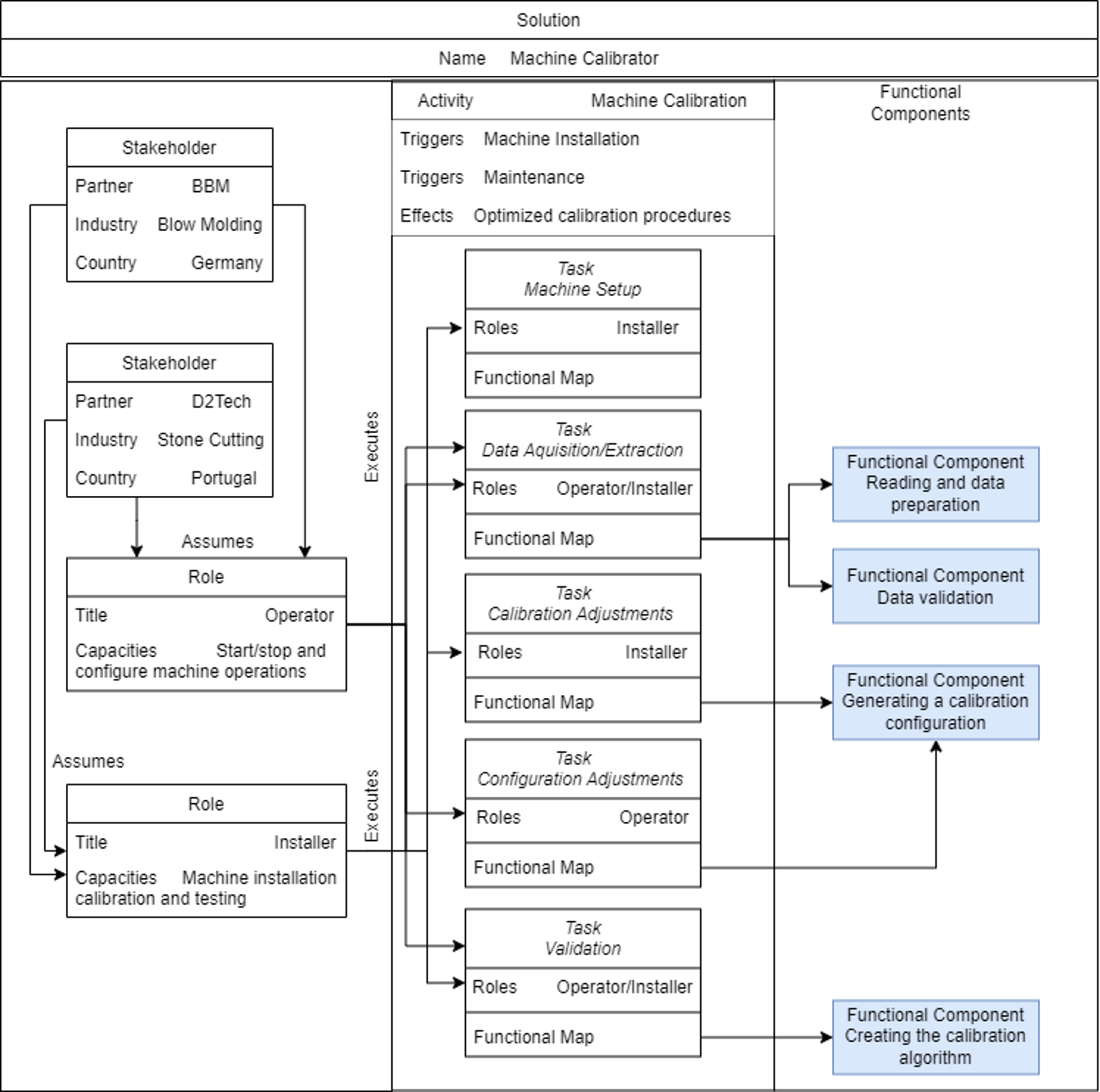

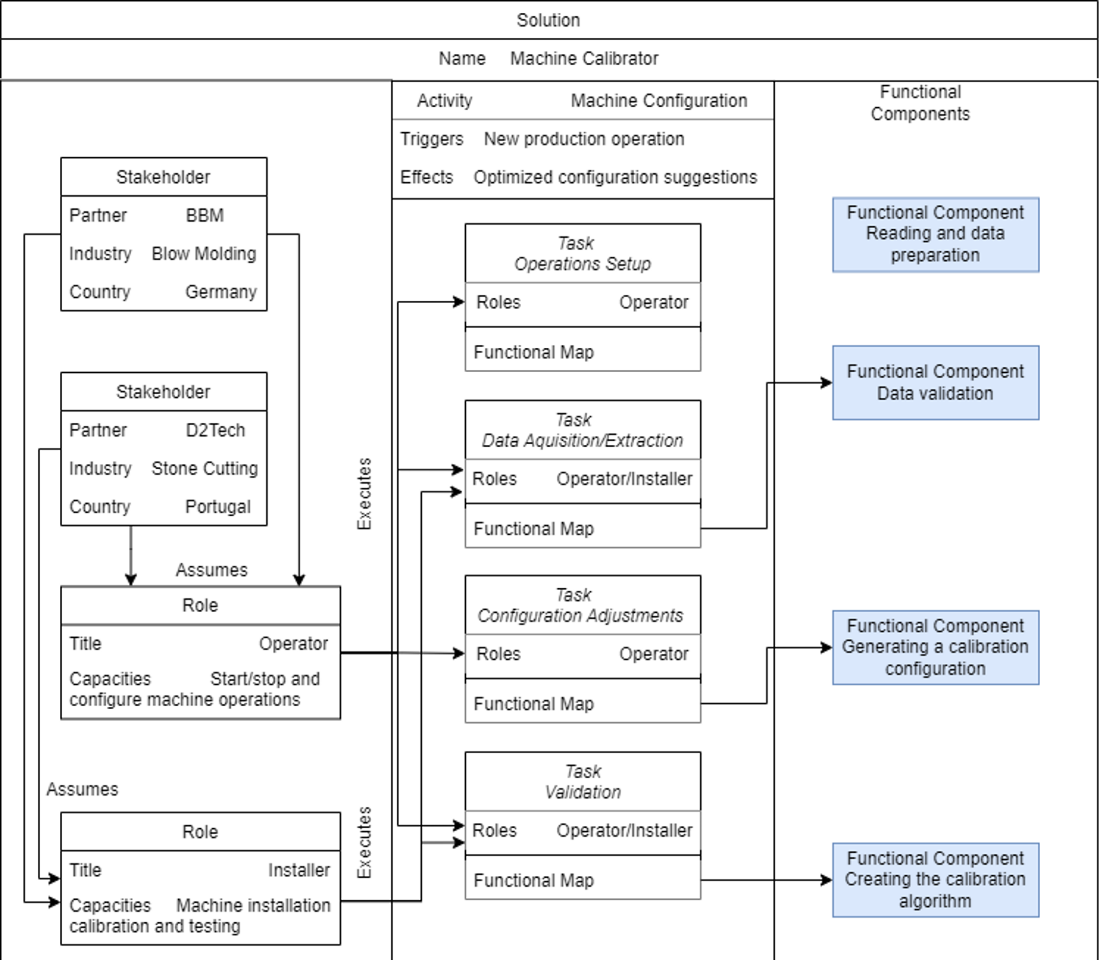

The following image demonstrates the interaction between the tasks and roles of D2TECH and BBM. This visual representation illustrates the dynamic flow of interactions, offering a representation of the activities executed by the solution. Through this diagram, the operational processes and collaborative engagements between different tasks and roles are presented, providing a clear understanding of the activities carried out by AIMC in its functioning.

Machine calibration¶

Machine configuration¶

Functional Viewpoint¶

Functional diagram¶

Functional description¶

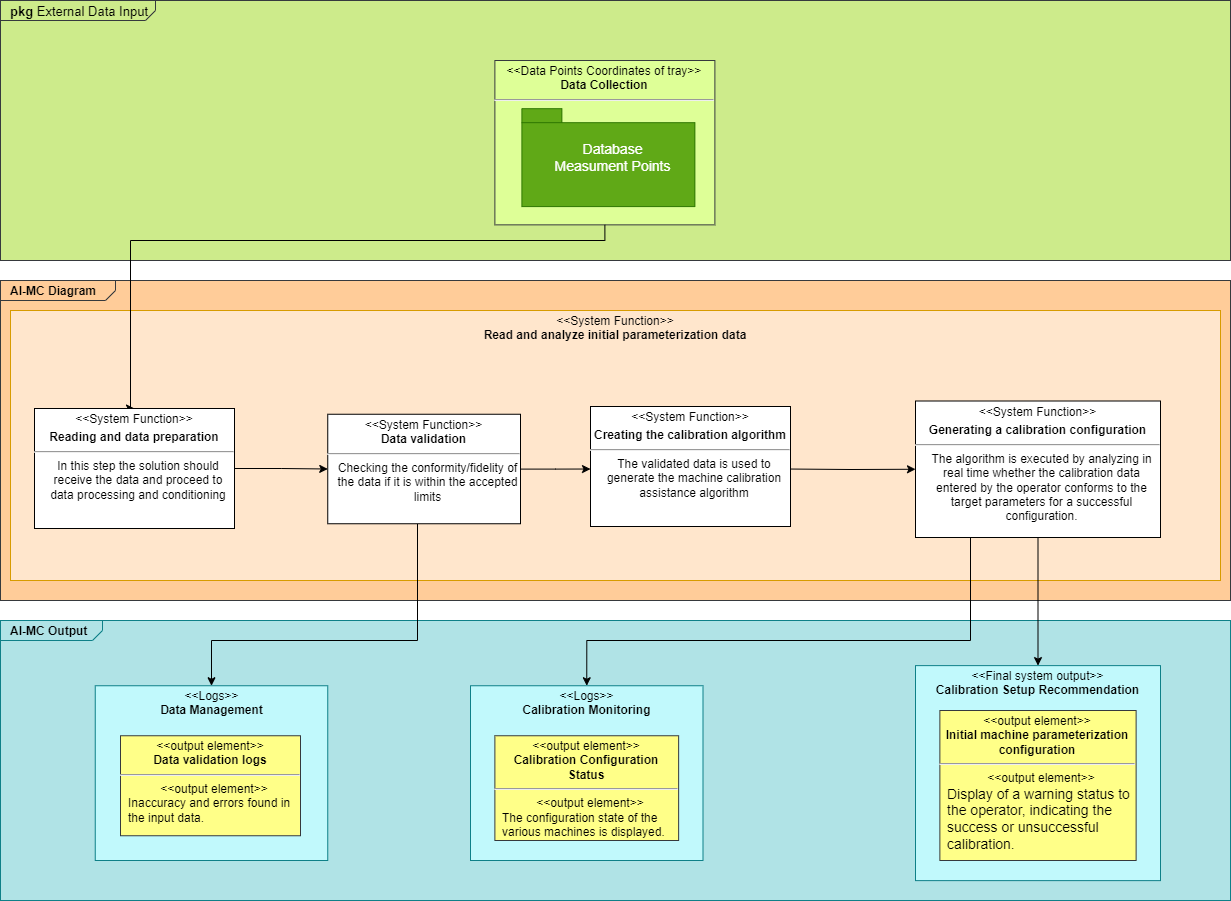

What: Assess machine installation conditions and provide calibration parameters.

Who: Machine Installer. Engineer

Where: Manufacturing and Use phases.

Why: Support the calibration of industrial equipment during the installation phase or when re-calibration is needed and reduce installation time and the skills required to calibrate the machine.

Input and output data for each component¶

Reading and data preparation¶

Inputs:

Measurment Points – Data points collected from the parts/components of the machine that require calibration.

Outputs:

Parameterized Data – Conditioned input data prepared for analysis and processing (i.e. serialized/normalized).

Data validation¶

Inputs:

Parameterized Data – Data prepared for validation.

Outputs:

Data validation Logs – Inaccuracies and errors detected in collected data points.

Creating the calibration algorithm¶

Inputs:

Validated Data Points – Validated data used to generate the machine calibration assistance algorithm.

Outputs:

Calibration Assistance Algorithm – The algorithm that will analyse the validated machine data points and process the required calibrations.

Generating a calibration configuration¶

Inputs:

Machine Data Points – Validated data points for calibration.

Outputs:

Calibration Monitoring – Calibration configuration status of the machines.

Calibration Setup Recommendation – Initial machine parameterization configurations and status.

Software requirements¶

Software Component |

Description/Role |

Required Version/Configuration |

Dependencies |

|---|---|---|---|

OS |

Base OS |

Linux (Ubuntu 22.04)/Windows 10 Pro |

N/A |

Docker |

Build, share and run containers |

latest |

N/A |

Lifecycle¶

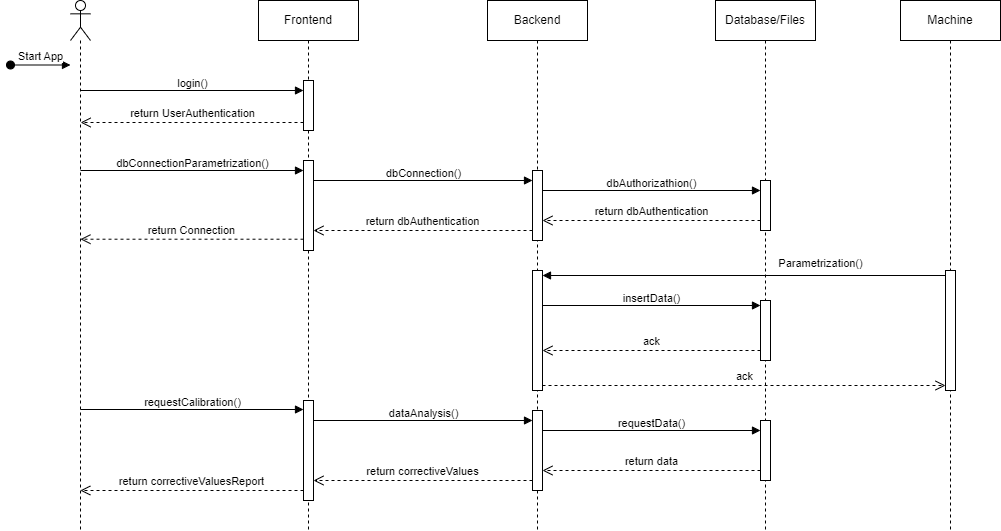

This sequence diagram illustrates the flow of interactions between the User, Frontend, Backend and Data/Files objects during the machine calibration processes. The parametrizations are reported by the machine sensors/controllers to the backend for storage and analysis, when the operator is performing the installation and calibration of the machines, presenting the corrective values in the frontend.

Objects¶

User: Represents the user interacting with the application

Frontend: Represents the user interface and the presentation layer.

Backend: Represents the application logic and the server layer.

Database/Files: Represents the data or file storage layer.

Machine: Represents the machine outputs.

Implementation Viewpoint¶

Description of implementation Component:¶

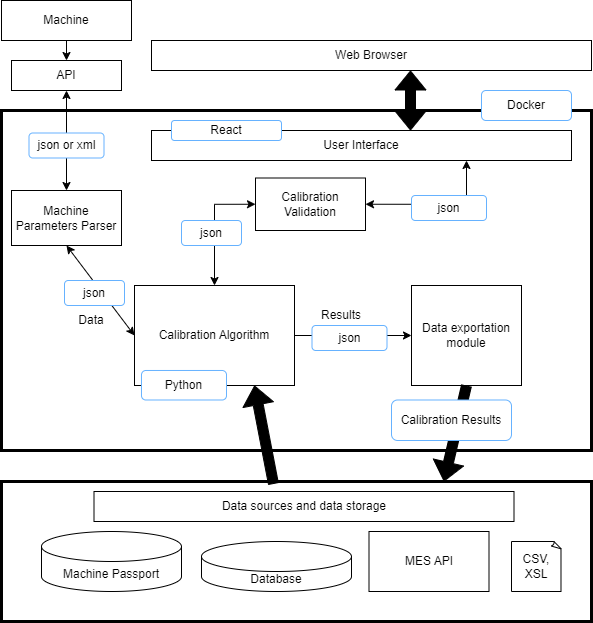

AI-MC is a toolkit to support the operator in the calibration of the machines.

Technical Description of its Components:¶

Dependencies:

Development Language: Python.

Libraries: Python ML libraries.

Container: Docker.

Database need: SQL Server or similar (eg MariaDB or PostGres).

Interfaces:

User Interface: REACT or similar.

Synchronous/Asynchronous Interface: RESTful APIs.

Network/Protocols: HTTP/HTTPS.

Data Repository: SQL Server or similar (eg MariaDB or PostGres).

Requires:

Other AIDEAS Solutions: none

Solution architecture¶

The MC solution will utilize the data gathered from machine operators regarding the initial equipment configuration to provide future parameter suggestions. The solution will be developed using Python, making use of comprehensive machine learning libraries. A SQL database will be employed within a Docker container environment to manage the data. Data inputs and outputs will be handled through a RESTful API, and the calibration suggestions, along with historical data, will be accessible to machine operators through a user interface designed using the REACT framework, following the project’s template. This approach aims to enhance the calibration process by leveraging machine learning techniques and providing an intuitive interface for operators to access and utilize the calibration suggestions.