Smart Retrofitter (SR)¶

General Description¶

The adoption of smart retrofitting solutions for old machines offers various benefits, including improving working conditions, enhancing the quality process, enabling better communication and collaboration, increasing productivity, efficiency, flexibility, and agility, and reducing costs. Here are the key aspects and considerations related to smart retrofitting:

Target Identification: Before designing a retrofit, it is crucial to identify the most strategic objectives for each pilot. These objectives may vary depending on the specific needs and priorities of the organization. By understanding the desired outcomes, the retrofit can be tailored to address the specific targets effectively.

Hardware Implementation: The retrofitting process involves the implementation of new hardware, such as IoT tools, to enable connectivity, data acquisition, plant control, and simulation of new scenarios. These hardware components enable the collection of data from the machines, creating a foundation for further analysis and optimization.

Data Acquisition and Control Platform: A platform will be developed to acquire data from the retrofitted machines, monitor their performance, and control the plant operations. This platform serves as a centralized system for managing and analyzing machine data, providing insights for decision-making and optimization.

AI Algorithms: AI algorithms will be implemented to perform various tasks, including pattern recognition, anomaly prediction, machine optimization, and planning. These algorithms leverage the collected data to identify patterns, detect anomalies, and optimize machine performance, enabling predictive maintenance, process improvement, and efficient resource allocation.

User Interface: A user interface will be developed to facilitate the operation of the retrofit solution. This interface should be user-friendly and accessible to heterogeneous user groups with varying levels of training and knowledge. The interface should be designed to accommodate different contexts and environments, ensuring usability across different scenarios.

Business Models: The retrofitting process presents an opportunity to develop new business models based on smart retrofitting of existing machinery. By extending the life of machine tools that would otherwise be discarded, customers can benefit from waste reduction and increased productivity, agility, and energy efficiency. These business models can offer both environmental and economic advantages to the customers.

Overall, smart retrofitting enables organizations to maximize the value and performance of existing machinery while also contributing to sustainability goals by reducing waste and improving energy efficiency. The combination of hardware implementation, data acquisition and control platforms, AI algorithms, user-friendly interfaces, and innovative business models forms the foundation for successful smart retrofitting initiatives.

Usage Viewpoint¶

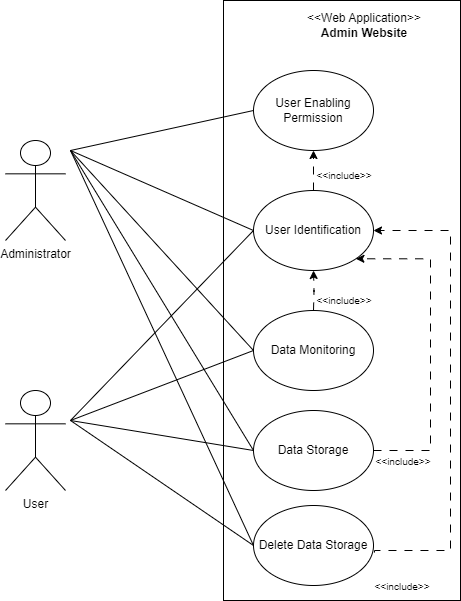

Use Model¶

Description¶

The SR (Smart Retrofitting) solution consists of both hardware and software components to monitor and control the consumption parameters of interest. Here are the key aspects of the software part:

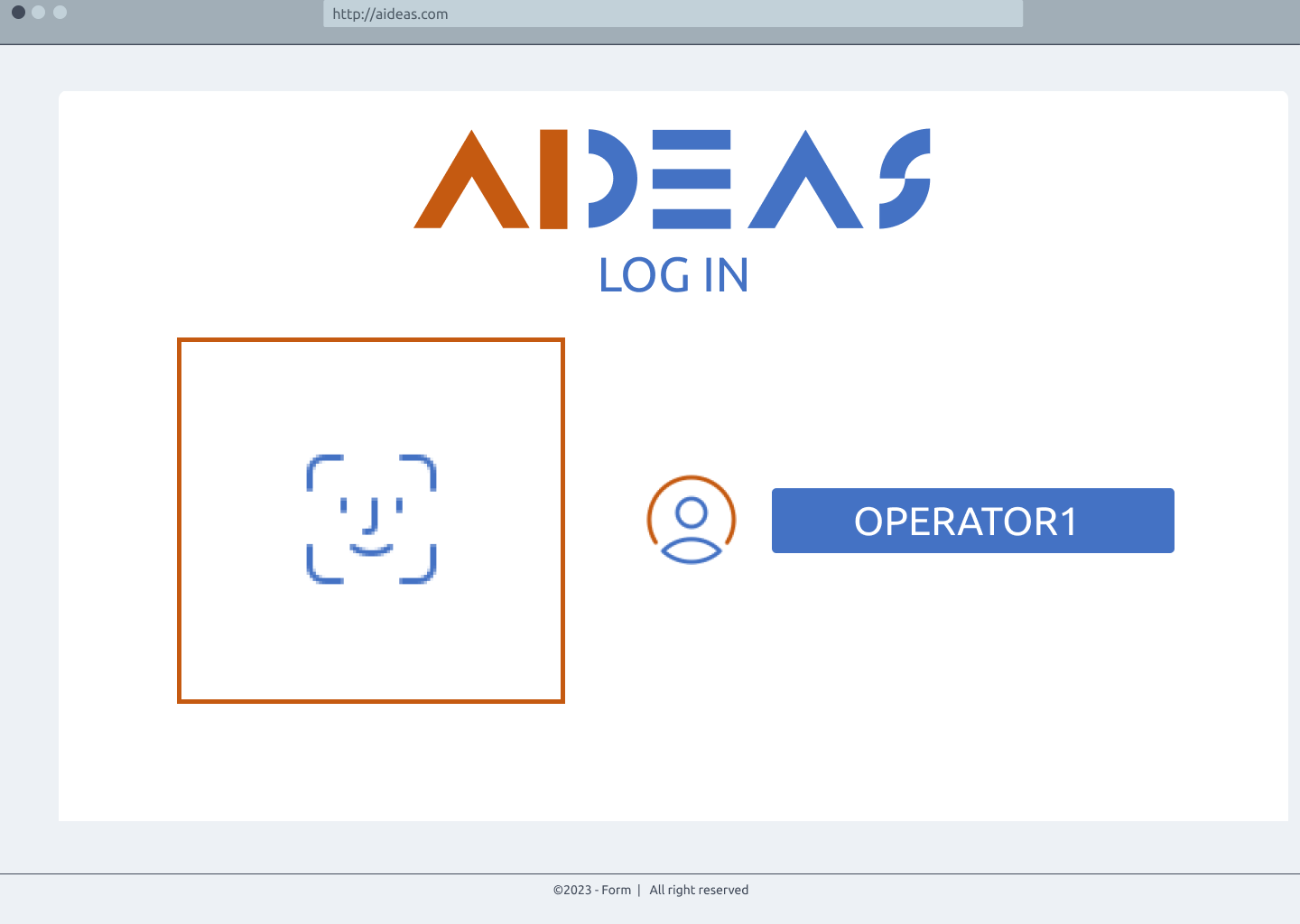

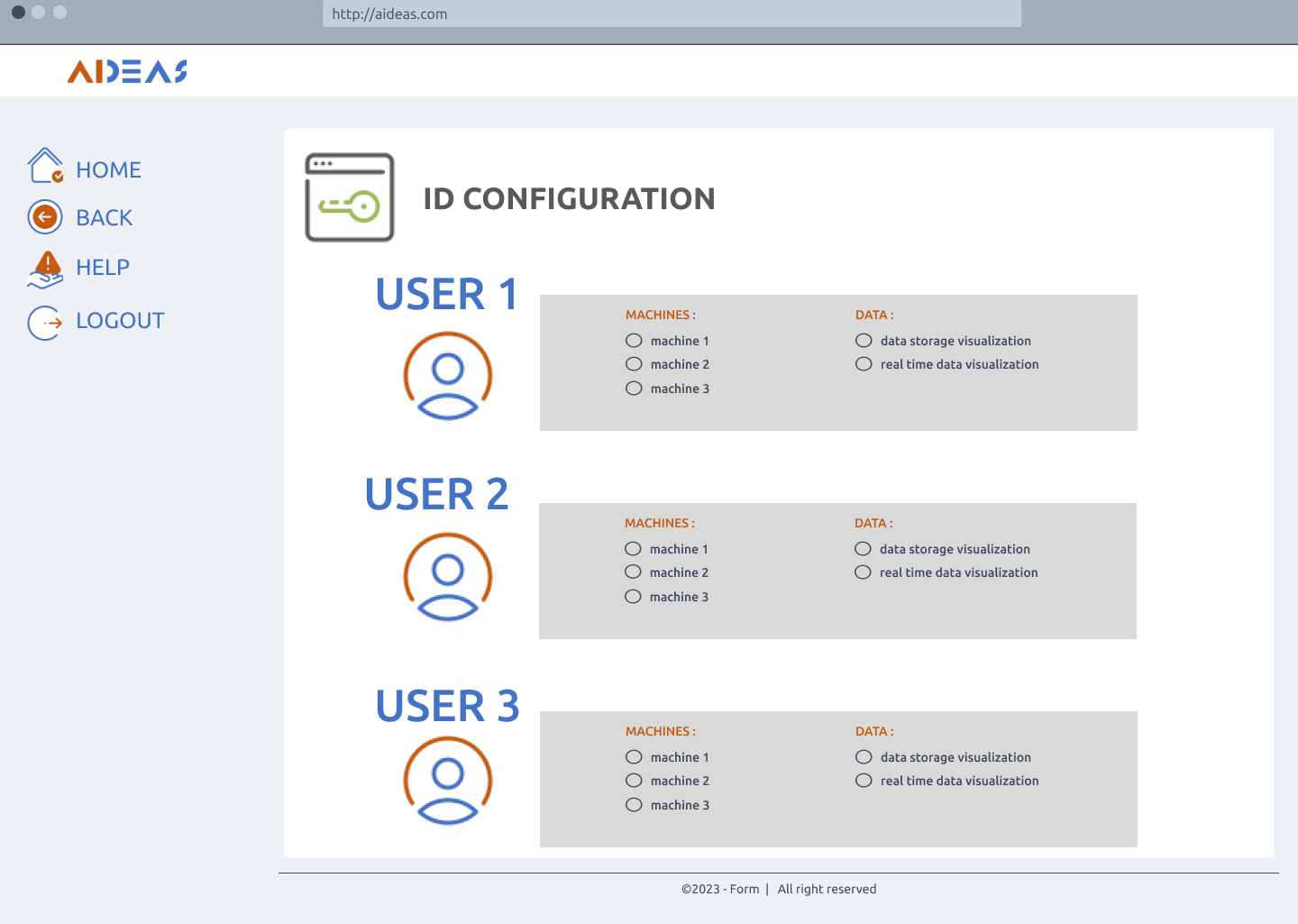

User Identification: The software includes a user identification system, which can be based on facial recognition or login ID. This ensures that only authorized individuals can access the system. Data access permissions are granted by the administrator, ensuring data security and privacy.

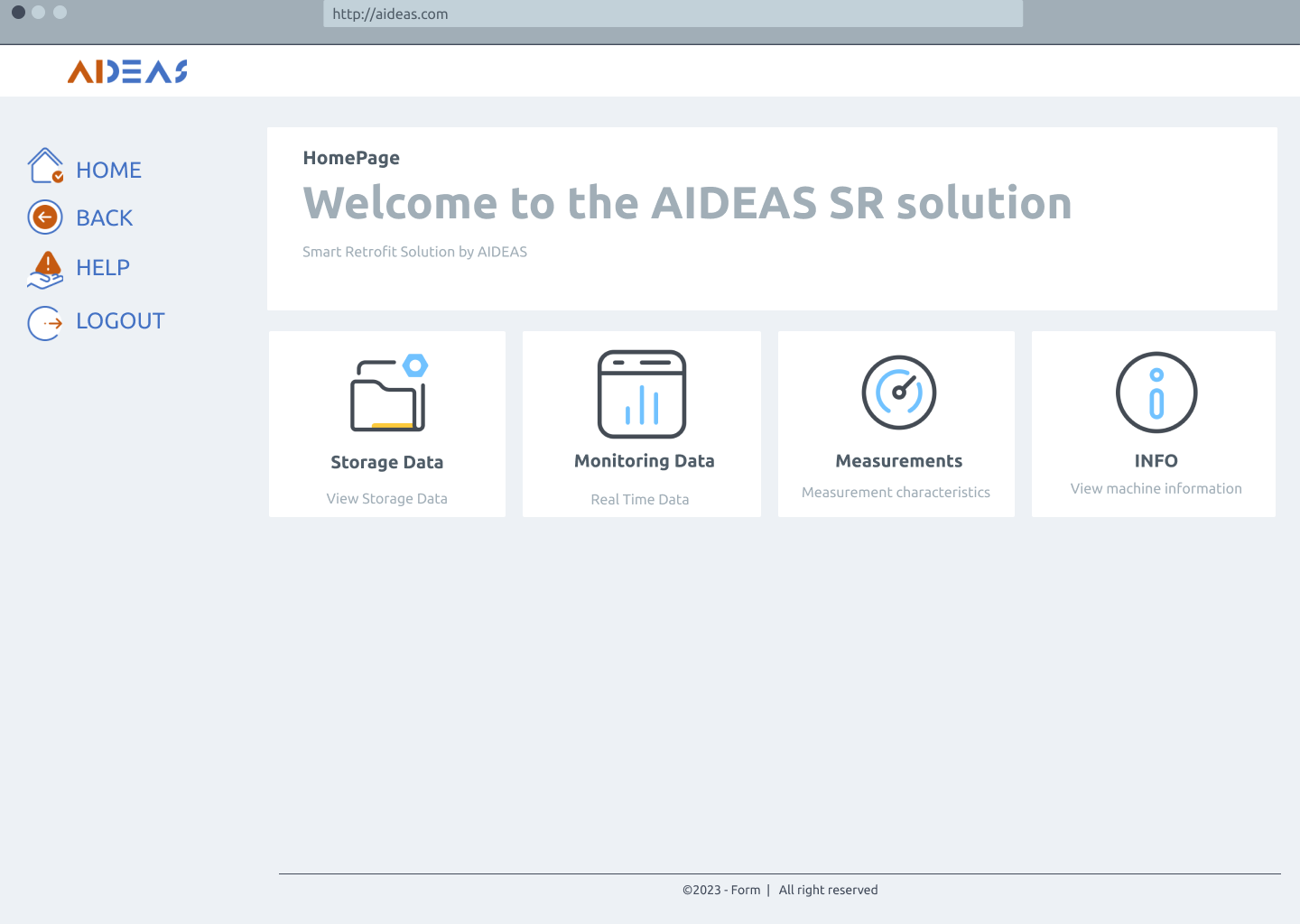

User Functions: Once logged in, users (both administrators and regular users) can perform various functions within the system. These functions can be managed and controlled by the administrator. The user interface provides a user-friendly environment for interacting with the system.

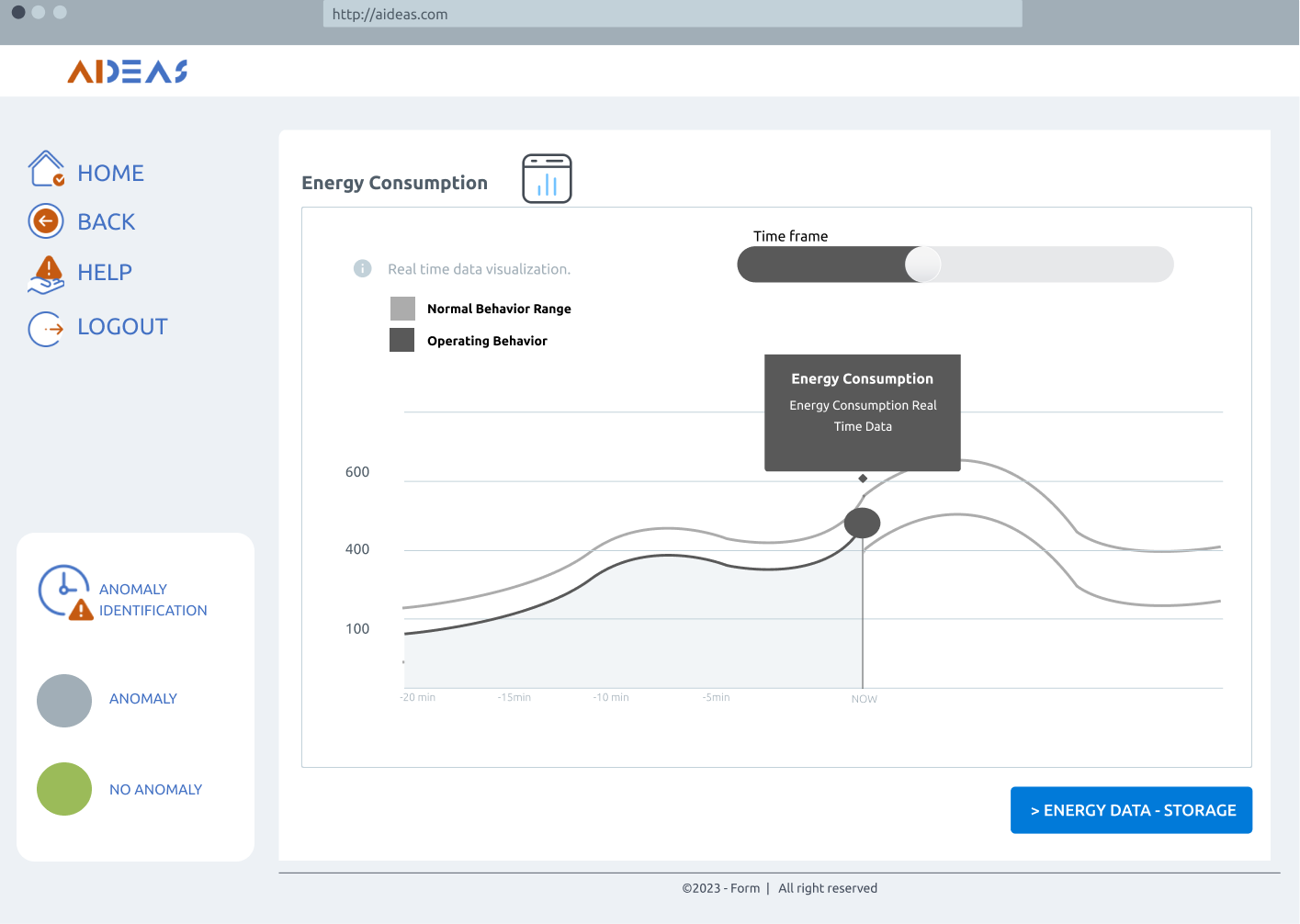

Real-Time Data Monitoring: The software enables users to view data in real time, allowing them to monitor the consumption parameters of interest as they are being measured. This real-time data monitoring provides immediate visibility into the system’s behavior.

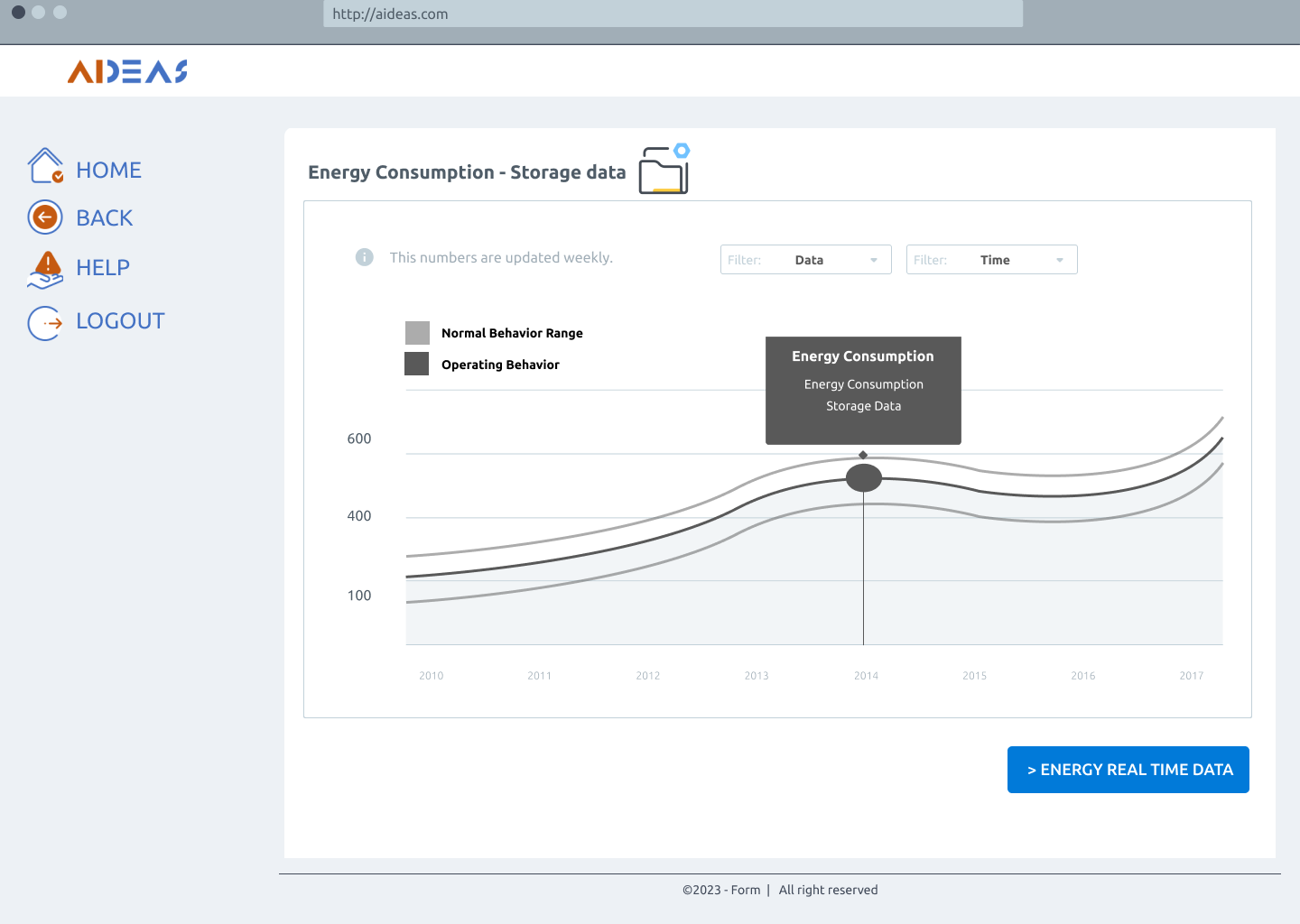

Data History: The software also provides the capability to view the historical data, allowing users to analyze past trends and patterns. This historical data can be useful for performance evaluation, identifying anomalies, and making informed decisions.

Behavior Control: The software incorporates an algorithm based on historical data to control the system’s behavior. This algorithm estimates the expected behavior of the consumption parameters and verifies their conformity within predefined threshold limits. If any parameters exceed the set limits, an alert message is sent and displayed on the Human-Machine Interface (HMI).

The integration of hardware and software components in the SR solution enables real-time monitoring, data analysis, and behavior control of the consumption parameters. The user-friendly interface, user identification system, and data access permissions ensure secure and controlled access to the system. By implementing threshold-based control and alert mechanisms, deviations from normal behavior can be identified promptly, allowing for timely corrective actions.

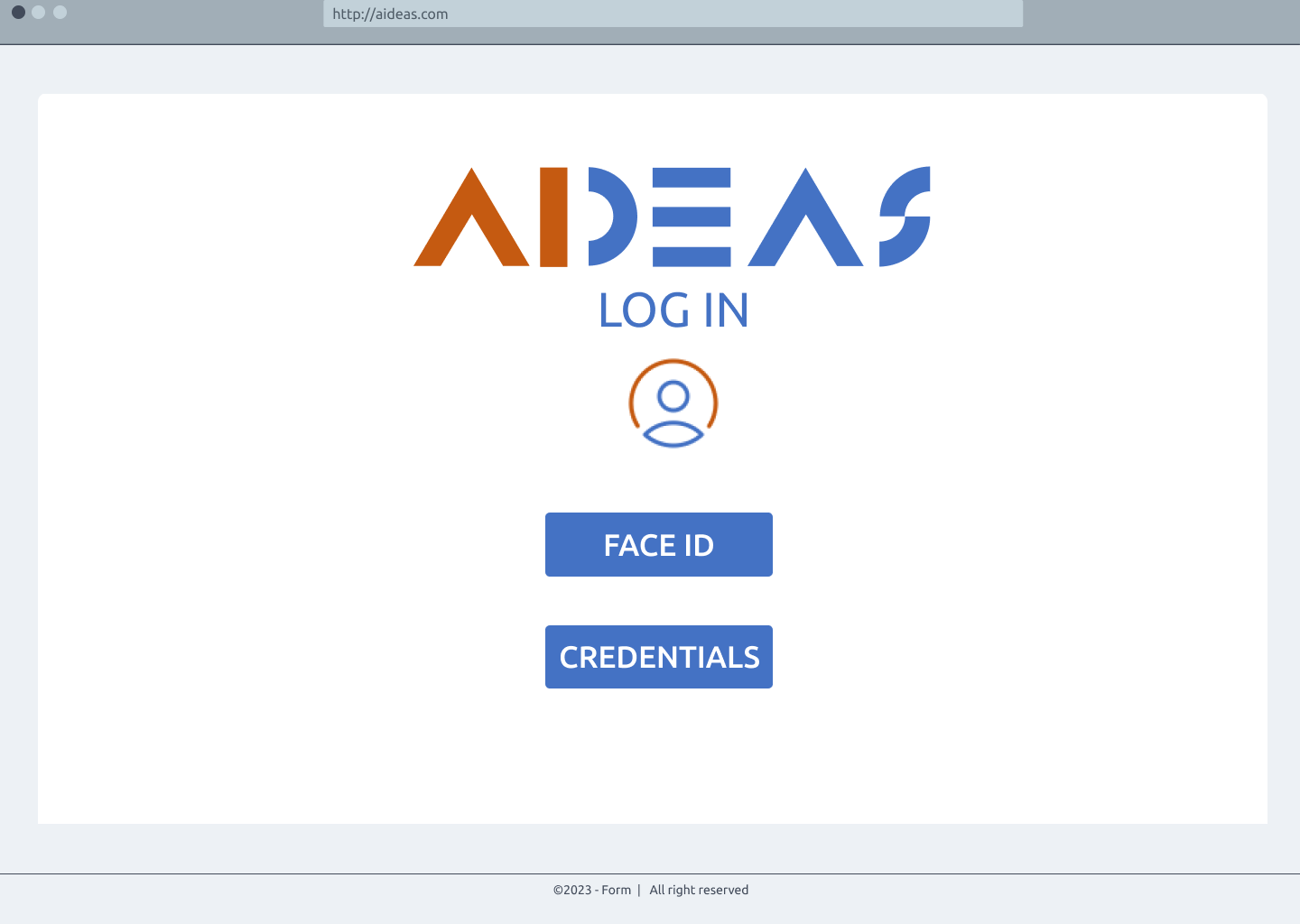

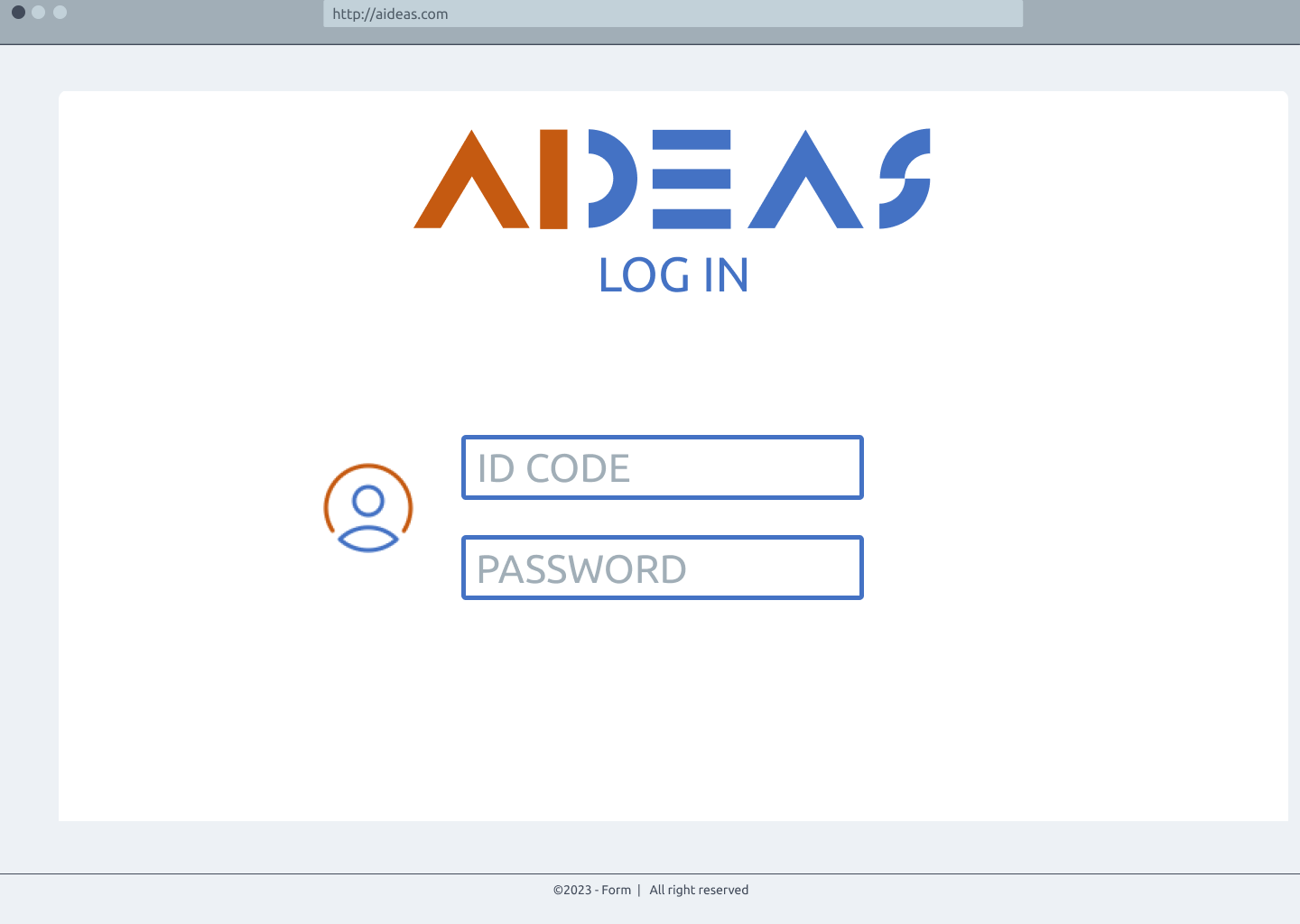

Login page¶

Identification¶

Face ID¶

ID configuration¶

Home page¶

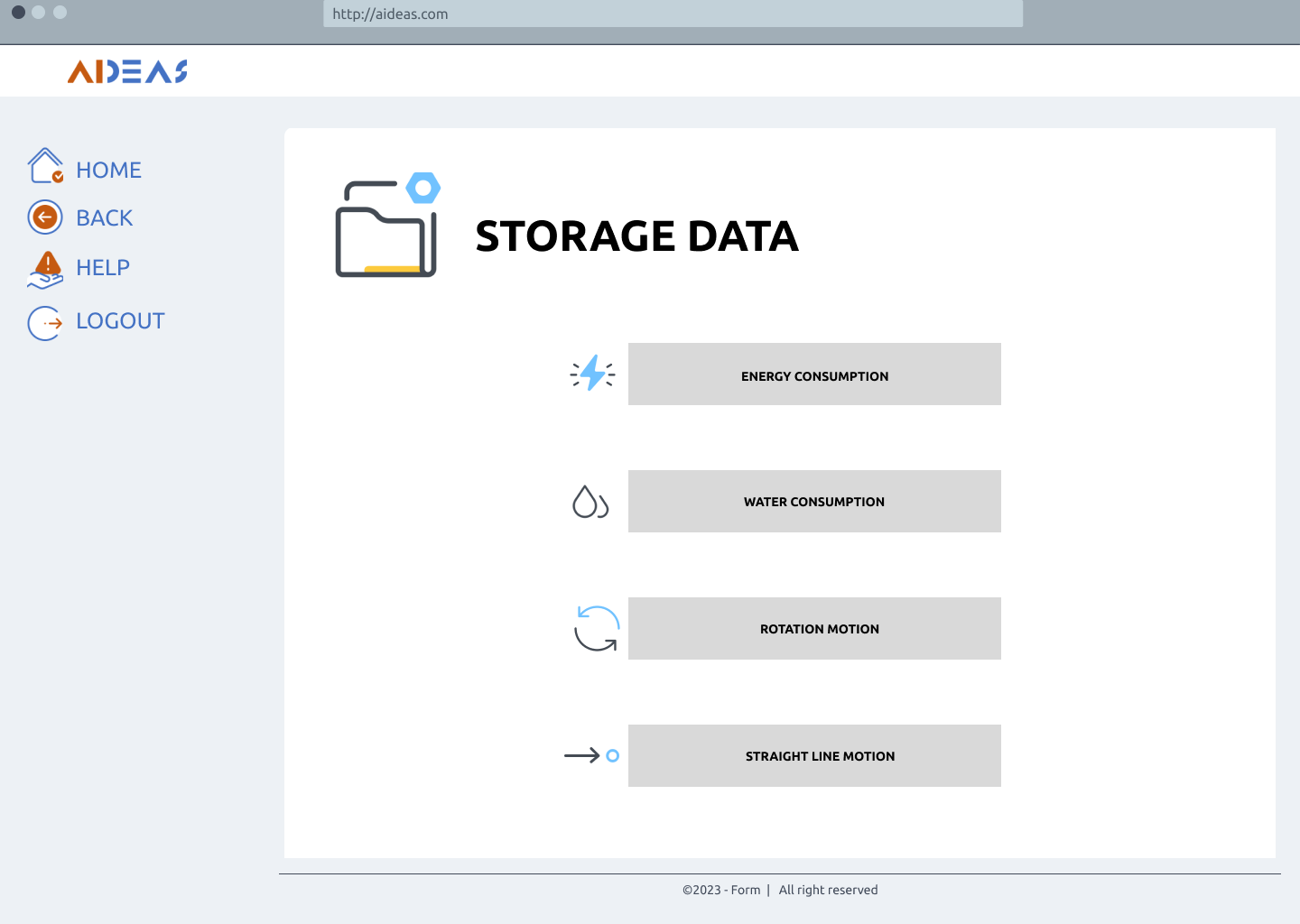

Storage data¶

Energy consumption data¶

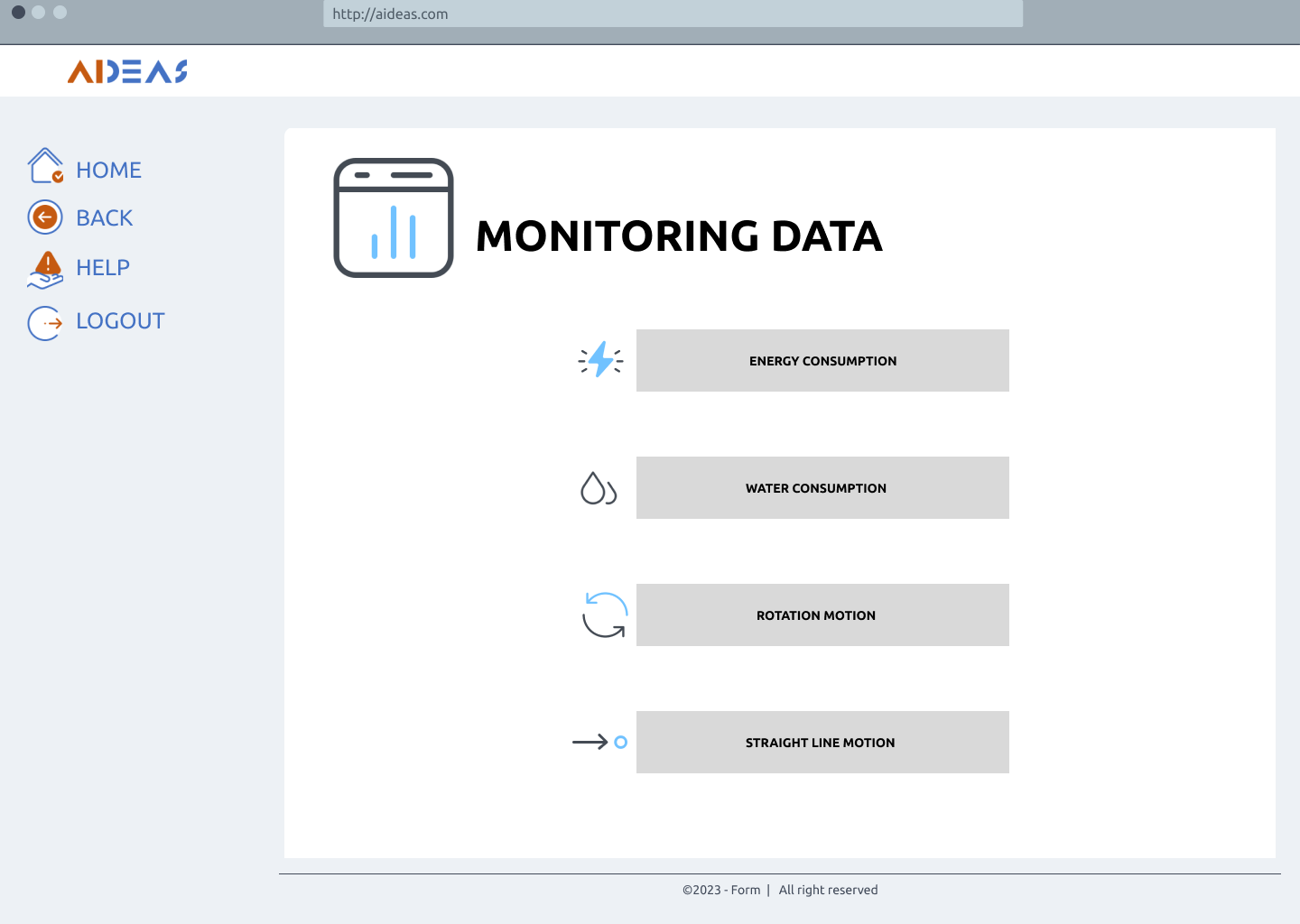

Monitoring data¶

Energy consumption monitoring¶

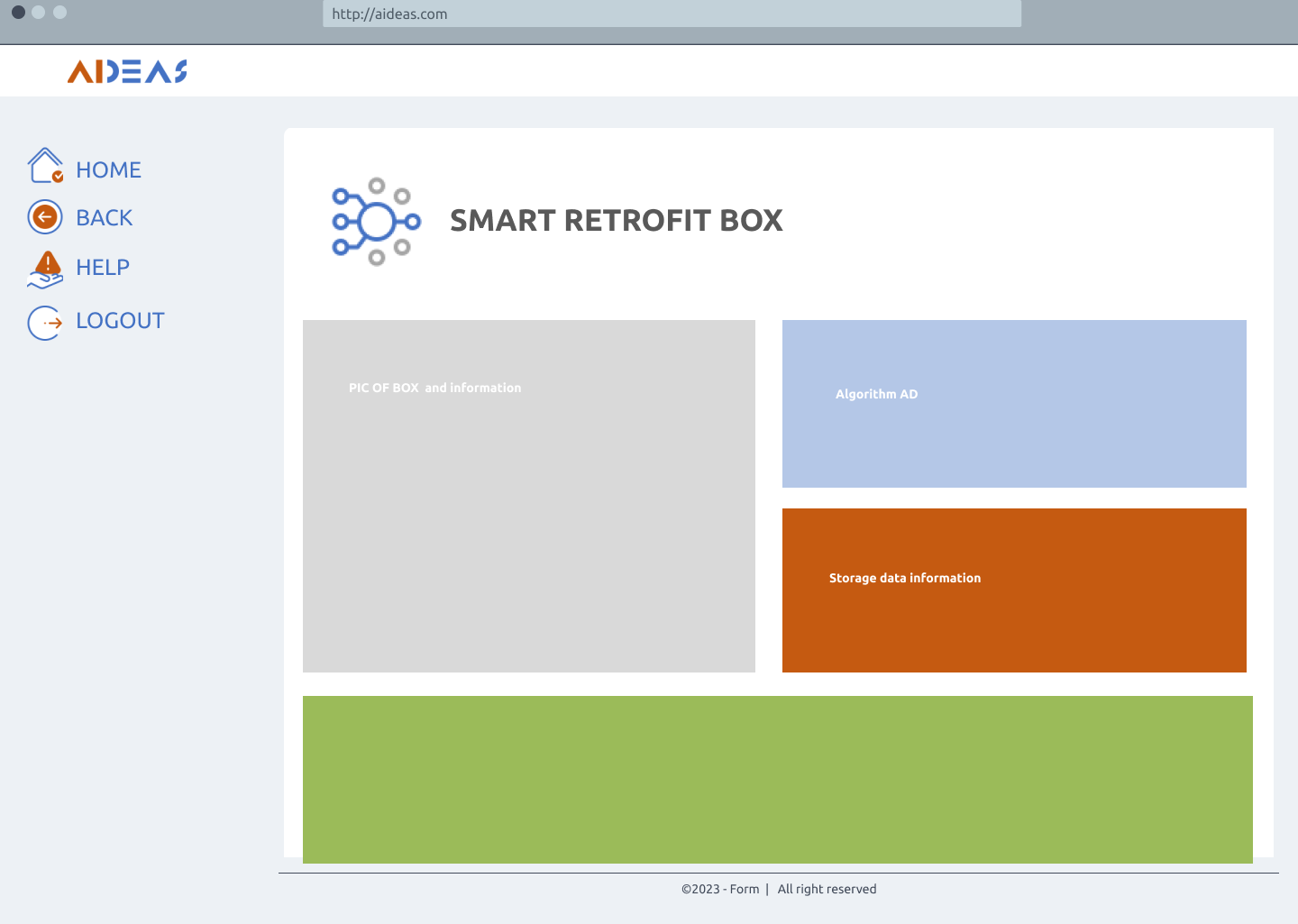

Smart retrofit box¶

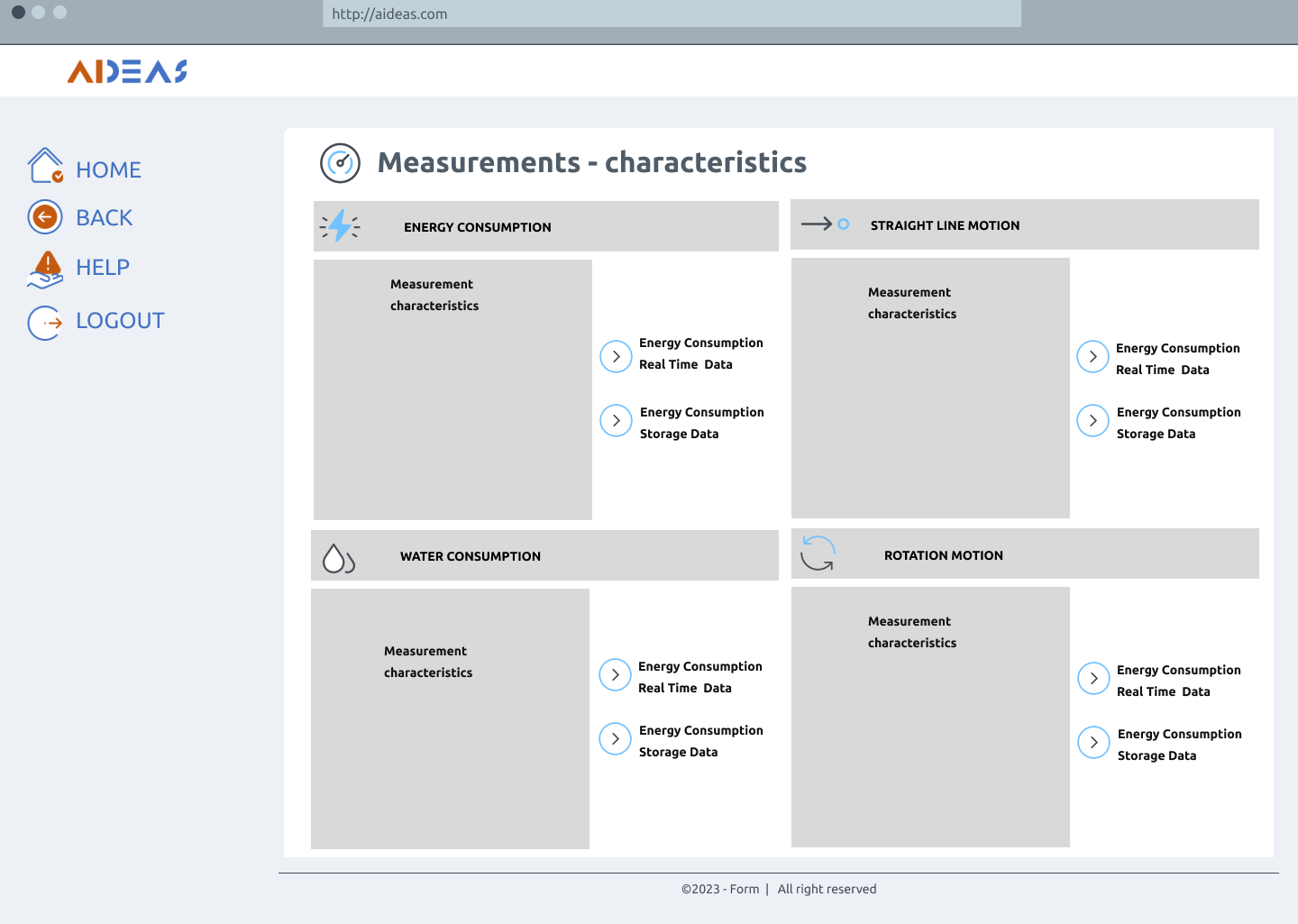

Measurements - characteristics¶

Information page¶

Usage activity diagram¶

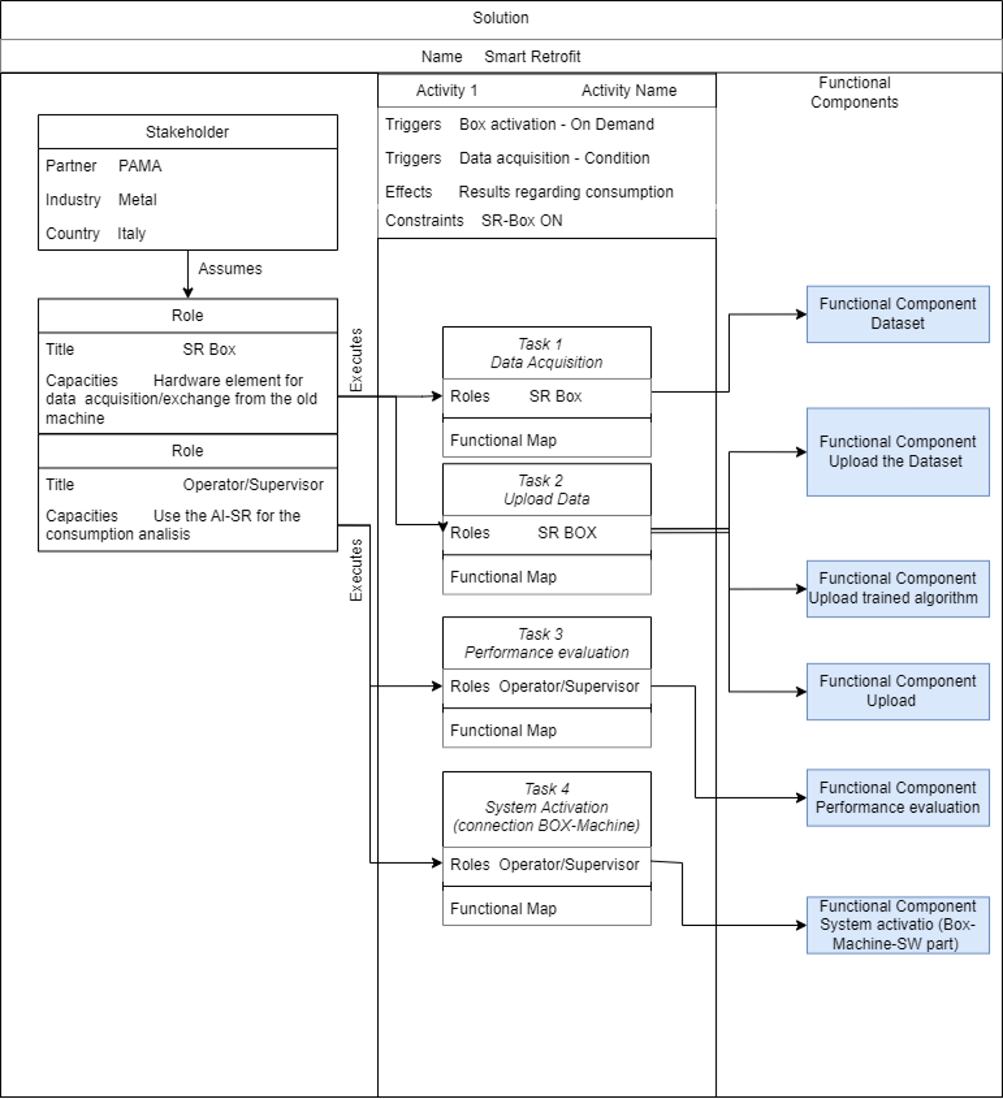

The following image shows the interaction between different tasks and roles. This diagram illustrates the dynamic flow of interactions, offering a representation of the activities performed by the solution and providing a clear understanding of the activities performed with the AISR solution.

Functional Viewpoint¶

Functional diagram¶

Functional description¶

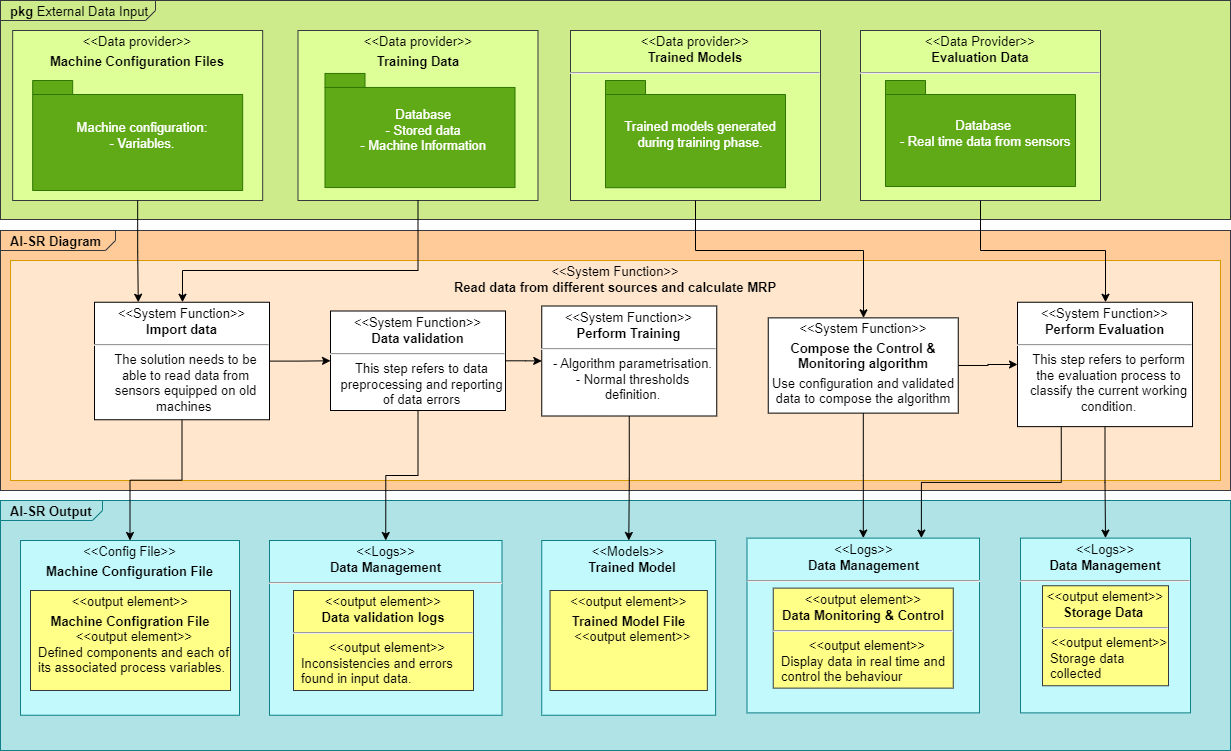

What: The main feature of this component is to monitor and control the behaviour of 4 parameters of interest. In addition, there is a section where you can view the stored data of the variables of interest.

Who:Production managers. Maintenance operators

Where: Old machines

Why: Unlike the new machines produced by D2T, the old machines do not have a system for monitoring and controlling certain parameters of interest or the associated connection to a centralised data collection system.

Input and output data for each component¶

Import Data¶

Inputs:

Data provided by sensors - water consumption, energy consumption, rotation and straight-line motion.

Data about machine configuration.

Outputs:

Data ready to use

Data Validation¶

Inputs:

Data are pre-processed and errors in the database are fixed

Outputs:

Correct and properly structured data

Perform Training¶

Inputs:

Correct and properly structured data

Outputs:

Algorithm parametrisation

Normal thresholds definition

Composing the control and monitoring algorithm¶

Inputs:

Trained models

Outputs:

Real time data and information about the behaviour of the machine.

Perform Evaluation¶

Inputs:

Real time data from sensors, processed by trained algorithm that considers the appropriate thresholds.

Outputs:

Storage data, Control of behaviour of the machine and display the trends.

Hardware requirements¶

Smart Retrofits’ solution involves the integration of a hardware part called the Smart Retrofit Box on the machine, which provides for the integration of all the devices required to bring the machine closer to the industry 4.0 paradigm. The SR-Box is designed to be generic and modular, thus adaptable to any situation. In fact, following a preliminary analysis on the machine, it is possible to identify if/which sensors are needed/present on the machine. Based on the initial conditions of the machine, the SR-Box is then integrated with new sensors or connected to existing ones. In this way, it is possible acquire all the parameters/data and carry out the desired analysis.

Hardware Element |

Importance and Explanation |

|---|---|

WiFi connection |

WiFi internet connection is necessary to realise the connection between the Smart Retrofit solution and the Cloud system. Alternatively, an intranet connection is enough to for SR operation |

Software requirements¶

Software Component |

Description/Role |

Required Version/Configuration |

Dependencies |

|---|---|---|---|

Linux OS or Windows OS |

Operating system needed to use the tool |

Ubuntu Debian / Windows 10 Pro |

N/A |

Docker |

Build, share and run containers |

latest |

N/A |

Lifecycle¶

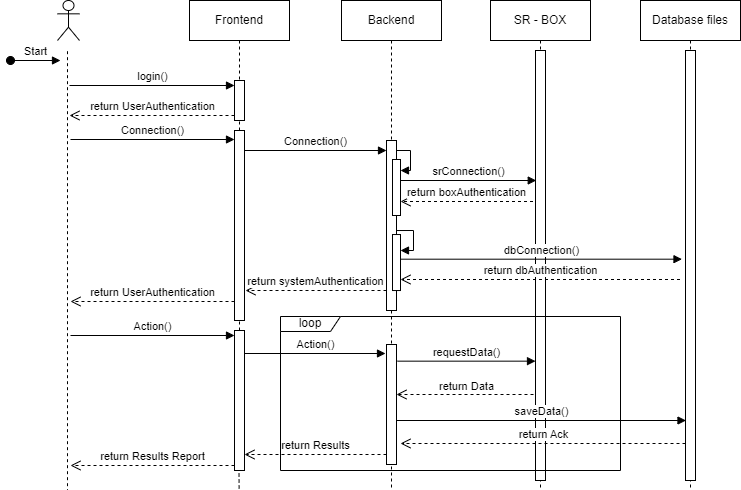

This sequence diagram illustrates the flow of interactions between the User, the Frontend, the Backend, the SR-Box objects, and the Database during the main processes. The user logs in to the AIDEAS platform, establish connections with the Box and the Database, initiate the main actions that request and process data to obtain useful results.

Objects¶

User: Represents the user interacting with the solution.

Frontend: Represents the user interface and the presentation layer.

Backend: Represents the application logic and the server layer.

SR-BOX: Represents the hardware/acquisition layer.

Database: Represents the data or file storage layer.

Implementation Viewpoint¶

Description of implementation Component:¶

AI-SR is for bring innovation to an old machine.

Technical Description of its Components:¶

Dependencies:

Development Language: - Python.

Libraries: Keras, sklearn, Numpy, Matplotlib, Pandas.

Container: Docker.

Database need: MySQL.

Interfaces:

User Interface: Wordpress

Synchronous/Asynchronous Interface: RESTful APIs

Network/Protocols: HTTP/HTTPS

Data Repository: MySQL

Requires:

Other AIDEAS Solutions: none

Solution architecture¶

![AI-SR[1360].drawio.png](_static%2Fimages%2FSR%2FAI-SR%5B1360%5D.drawio.png)

The AI-SR tool will be developed using Python as the programming language, leveraging popular data science libraries such as NumPy, Pandas, and Keras/sklearn. These libraries provide robust functionality for data processing, analysis, and machine learning algorithms.

For data visualization, the Matplotlib tool will be utilized, allowing for the creation of informative and visually appealing plots and charts.

The front-end development of the AI-SR solution will be implemented using WordPress software. WordPress provides a user-friendly interface and flexible customization options for building the front-end components of the tool.

To facilitate communication between the back-end and front-end, a RESTful API will be employed. This API will enable secure data transmission over HTTPS protocols, ensuring the confidentiality and integrity of the exchanged information.

The actual data will be stored in a MySQL database, providing a reliable and scalable solution for data storage and retrieval.

To streamline the deployment process and ensure software portability, Docker will be utilized. Docker allows for the encapsulation of all the necessary components and dependencies into containers, making it easier to deploy the AI-SR tool across different environments and systems.

By leveraging these technologies and frameworks, the AI-SR tool can be efficiently developed, deployed, and maintained, enabling effective monitoring and control of consumption parameters for retrofitting purposes.