Delivery Optimiser (DO)¶

General Description¶

The primary objective of this tool is to enhance the efficiency of product packaging, storage, and delivery processes. To achieve this, AI applications will assist users in developing optimized plans and strategies for logistics, ensuring timely delivery to customers. Additionally, the optimization efforts will focus on space utilization within the manufacturer’s storage facilities, accounting for potential disruptive events. Ultimately, the AI applications aim to maximize the responsiveness and agility of the supply chain between the manufacturer and customers.

Usage Viewpoint¶

Use Model¶

Description¶

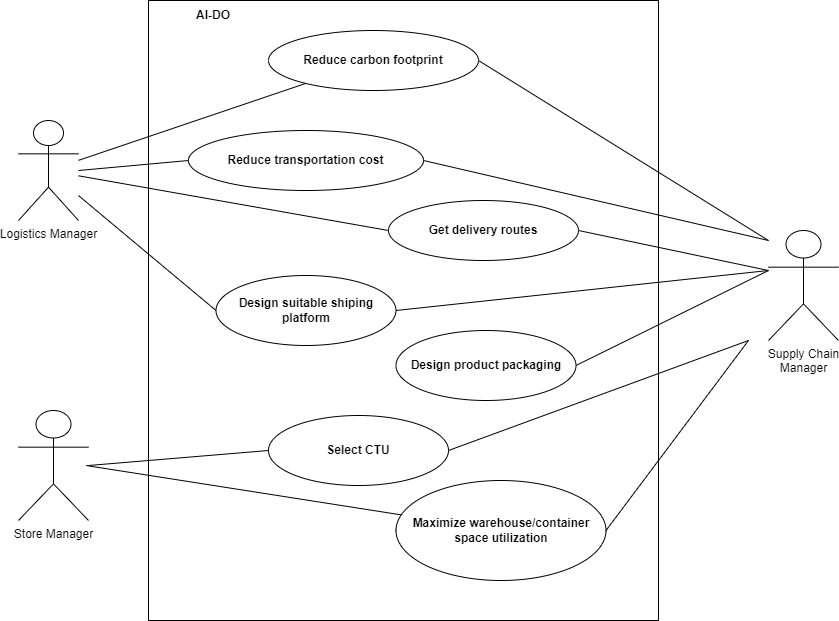

The delivery optimizer solution caters to various key stakeholders, including the logistics manager, store manager, and supply chain manager, who benefit from its functionalities. By leveraging AI algorithms, the AI-DO streamlines the entire process, starting from packaging a machine or machine part to its subsequent storage or delivery to the customer.

For instance, the supply chain manager can utilize the AI-DO to predict essential parameters that facilitate packaging design, such as packaging size, material selection, and fragility considerations. Similarly, the store manager can take advantage of the AI-DO’s solutions to obtain layout designs for efficient storage in the warehouse or placement in the Container Transport Unit for delivery purposes.

Once the product is prepared for delivery, the logistics manager can rely on the AI-DO’s offerings to acquire predicted parameters like estimated time of arrival, transportation cost, optimal route, and CO2 consumption. These predictions empower the logistics manager to make informed decisions on delivery options that align with specific requirements and restrictions.

Home page¶

Packaging Optimizer Parameters¶

Storage Optimizer Parameters¶

Delivery Optimizer Parameters¶

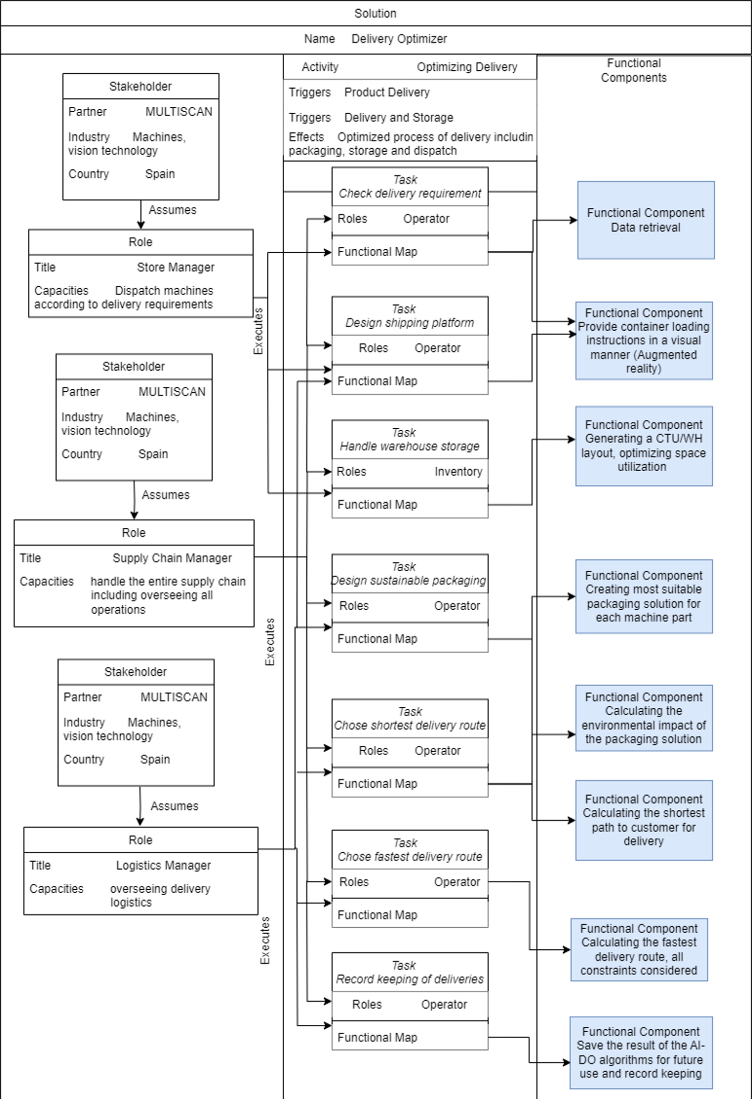

Usage activity diagram¶

The following image illustrates the connections between the tasks and roles in the MULTISCAN use-case. This usage activity diagram shows the flow of activities performed by the AIDO solution. The roles, tasks, processes, and functional components help to provide a clear understanding of the activities executed using the AIDO solution.

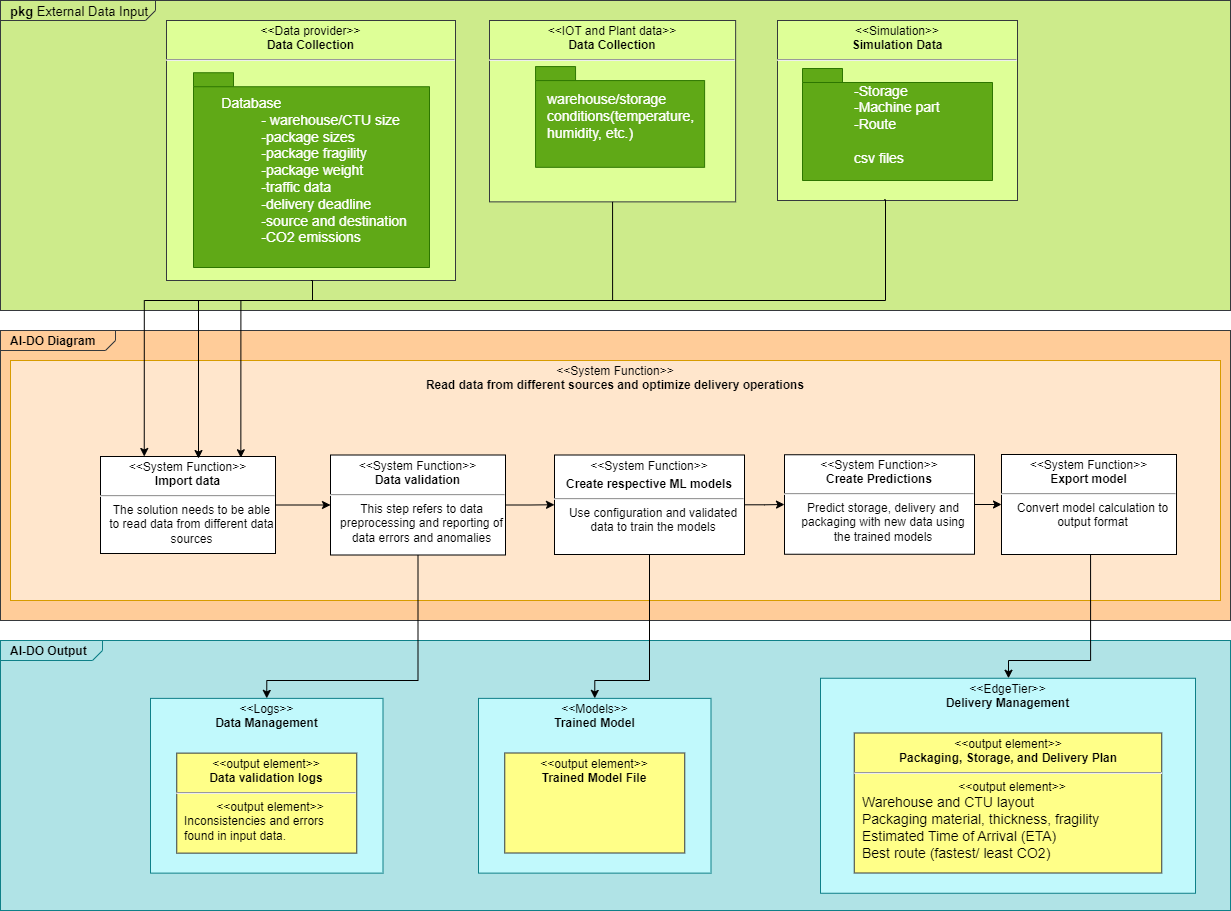

Functional Viewpoint¶

Functional diagram¶

Functional description¶

What: Suggests optimal packaging for the machine part inputted to the component, including packaging material, package thickness and need for extra protection.

Who: Storage manager, Logistics manager, Supply chain manager.

Where: Edge Tier (at client level).

Why: Aim of the packaging optimizer is to improve the packaging used for machinery parts. It will help in quickly finding the best possible packaging (packaging material, packaging thickness), for a machine part, thus improving the package safety and reduce packaging cost and packaging waste over alternatives such as manual packaging.

Input and output data for each component¶

Packaging optimizer¶

Inputs:

Machine part dimensions: Length, width, and height of machine part.

Part weight: Weight in kgs of the machine part.

Part composition: Percentage composition of the machine part e.g., Alloy, plastic, glass.

Part fragility: Machine part fragility on a scale of 1 to 5, where 1 is the lowest and 5 is the highest.

Part storage time: For how many days will the part be kept in storage/be in transport before being delivered to customer.

Atmospheric seal: Binary value stating whether or not the part needs to be atmospherically sealed.

Outputs:

Packaging material: What material should the packaging be made of, can include plastic wrap, paperbox, corrugated box, cardboard box and plastic box.

Package thickness class: How thick the packaging should be, can be one of either three classes of thickness.

Extra protection requirement: Whether to include extra protective material in the final packaging.

Package fragility: The final fragility level of the packaged part. Can be one of either three classes of fragility.

Storage Optimizer¶

Inputs:

Storage dimensions: Either the warehouse dimensions or the CTU dimensions.

Storage conditions: Can include warehouse temperature, humidity level etc.

Package sizes: Dimensions of the package to be stored.

Package fragility: Fragility class of the packaged to be admitted to warehouse.

Outputs:

Warehouse allocation: Where in the warehouse the package will be stored, will also include information on how to retrieve it.

Storage conditions: Ideal storage conditions based on the package requirement, such as the temperature and humidity level, whether the package can be rotated or stacked or not based on fragility level.

CTU layout: The ideal CTU layout in order to maximize volume utilization within the CTU.

Delivery optimizer¶

Inputs:

Traffic data: traffic data on a scale of 1 to 10, 1 being the lowest and 10 the highest amount of traffic at any given time.

Deadline: Deadline, in the number of days for a specific delivery.

Origin and Destination: The start point and final destination of the delivery.

CO2 emission data: Emission data by destination and mode of delivery.

Historical delivery data: historic data of past deliveries.

Delivery costs: Costs associated with delivery, most of this data comes from historical data.

Delivery mode: which mode will be primarily used for delivery, either land, air or sea.

Outputs:

ETA: estimated time of arrival (in days) for a delivery.

Fastest route: fastest route based on the least number of days.

Least CO2 route: Route which uses the least amount of CO2, may not be the fastest or even the cheapest route.

Grouped shipping: possible options to combine deliveries into one shipment based on parameters provided in the input.

Delivery cost: Cost of delivery, also shows the cost of delivery in the prior suggested routes, such as fastest route.

Hardware requirements¶

Hardware Element |

Importance and Explanation |

|---|---|

AR Hardware and Android device |

For the visualization of the AIDO results and output. This is needed to support the human worker to implement the optimal solution provided by the tool e.g., a guide on how to arrange the machine parts in the boxes and in the shipping container. The AR hardware should be capable of running an HTTPS server. The Android device should have Chrome 81 or newer installed |

Software requirements¶

Software Component |

Description/Role |

Required Version/Configuration |

|---|---|---|

Windows OS |

Microsoft operating system its need to use specific tool |

Windows 11 |

Microsoft Office Suite |

Suite of office with excel applications for document processing. |

Office 365 |

Lifecycle¶

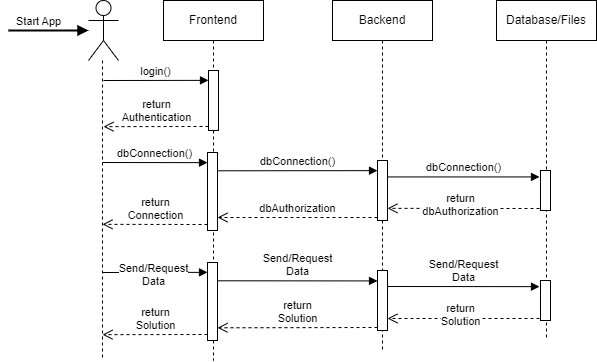

This sequence diagram illustrates interactions between the Frontend, Backend and Database. The user will have to login via the AIDEAS platform. The output of the AI model (optimised solution for packaging, storage, and delivery) is visualized on the Frontend.

Objects¶

User: Represents the user interacting with the application.

Frontend: Represents the user interface and the presentation layer.

Backend: Represents the application logic and the server layer.

Database/Files: Represents the data or file storage layer.

Implementation Viewpoint¶

AI-DO is for optimization of machine packaging and delivery.

Technical Description of its Components:¶

Dependencies:

Development Language: - Python.

Libraries: Pymoo, sklearn.

Container: Docker.

Database need: MongoDB, Postgres.

Interfaces:

User Interface: Yes, REACT.

Synchronous/Asynchronous Interface: RESTful APIs.

Network/Protocols: HTTP/HTTPS.

Data Repository: MongoDB.

Requires:

Other AIDEAS Solutions: none

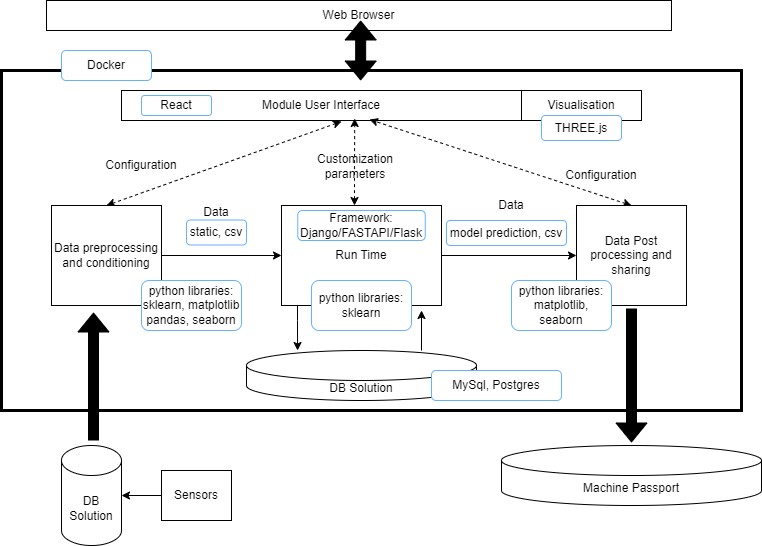

Solution architecture¶

Python, being a versatile language for data processing and machine learning, serves as the primary development language for the delivery optimizer. To handle data preprocessing, cleaning, and model training, the sklearn library will be predominantly utilized. For efficient multi-objective optimization, the pymoo library will be employed.

To ensure seamless deployment and containerization, the Docker platform will be utilized. As for the database requirements, MongoDB has been chosen due to its flexibility, ease of use, and simplicity.

In terms of the user interface, we have opted for REACT, given its widespread adoption and familiarity within our in-house expertise. The communication between the frontend and backend will be facilitated through Restful APIs, utilizing the HTTP and HTTPS network protocols.